QMH_Qingdao Quality Material Handling Co., Ltd. focuses on the field of bulk material transportation, integrating product research and development, production, sales and technical services, serving customers in multiple industries such as metallurgy, mining, underground space, power plants, ports, and chemicals around the world; The QMH team has more than 30 years of experience in material handling technology and on-site problem solving, and is committed to the green development of industrial transportation. QMH provides customers with personalized solutions to meet their needs for "the best and most efficient conveying systems".

QMH provides customers with a one-stop & cost-effective conveying system product solution, including European standard long-life conveyor belts, conveyor systems and components, pulley lagging, wear linings, conveyor belt repair materials, splicing materials and other related products.

QMH production base is located in Haiyang City, Yantai City, Shandong Province, China. The factory covers a total area of 50 acres and a total construction area of 20,000 square meters. The factory has 7 technical R&D personnel and 100 production personnel. It has its own conveyor belt mixing, calendering, laminating, vulcanization and other production lines. The production lines use fully intelligent equipment and its production capacity ranks top in the industry.

Over the years, it has been successively rated as a national high-tech enterprise, a smart factory demonstration enterprise, a conveyor belt national industry standard setting enterprise, and has passed the ISO three-system certification.

QMH has 10 semi-finished product production lines, 4 finished sidewall vulcanization lines, canvas belt production lines, steel cord conveyor belt production lines, B2300 calendering lines, mixing lines, cold-adhesive glue and other production line equipment. Among them, the steep sidewall adopts a full set of European molds and European standard production processes. QMH can produce steep sidewall, canvas belt, steel cord conveyor belt, anti-overflow skirt, roller rubber, buffer strip, repair materials, cold-adhesive glue and other products.

QMH is committed to providing users with an overall solution for technical consulting services for new projects, and can also provide professional advice and help at any time for the pain points of users in the use of conveyors/conveyor belts.

QMH can provide a full range of system diagnostic services related to conveyors, issue diagnostic reports and provide customized solutions to help customers extend the service life of conveyors and reduce operating costs.

QMH can provide users with customized R&D services for conveyor belt products, and provide product selection guidance based on transportation distance, conveying volume, motor power, turning angle, material characteristics, operating conditions, etc.

QMH can provide online and offline technical training for on-site personnel of the conveying system on conveyor belt joint technology, cold bonding technology, quick joints, quick repairs, dust removal measures at transfer points, common maintenance measures for conveying systems, intelligent operation and other related content.

Applicable to bulk material transportation, the product can be used in the following industries: Mining, coal, metallurgy, tunnels, water conservancy, chemical industry, power, ports, cement, etc.

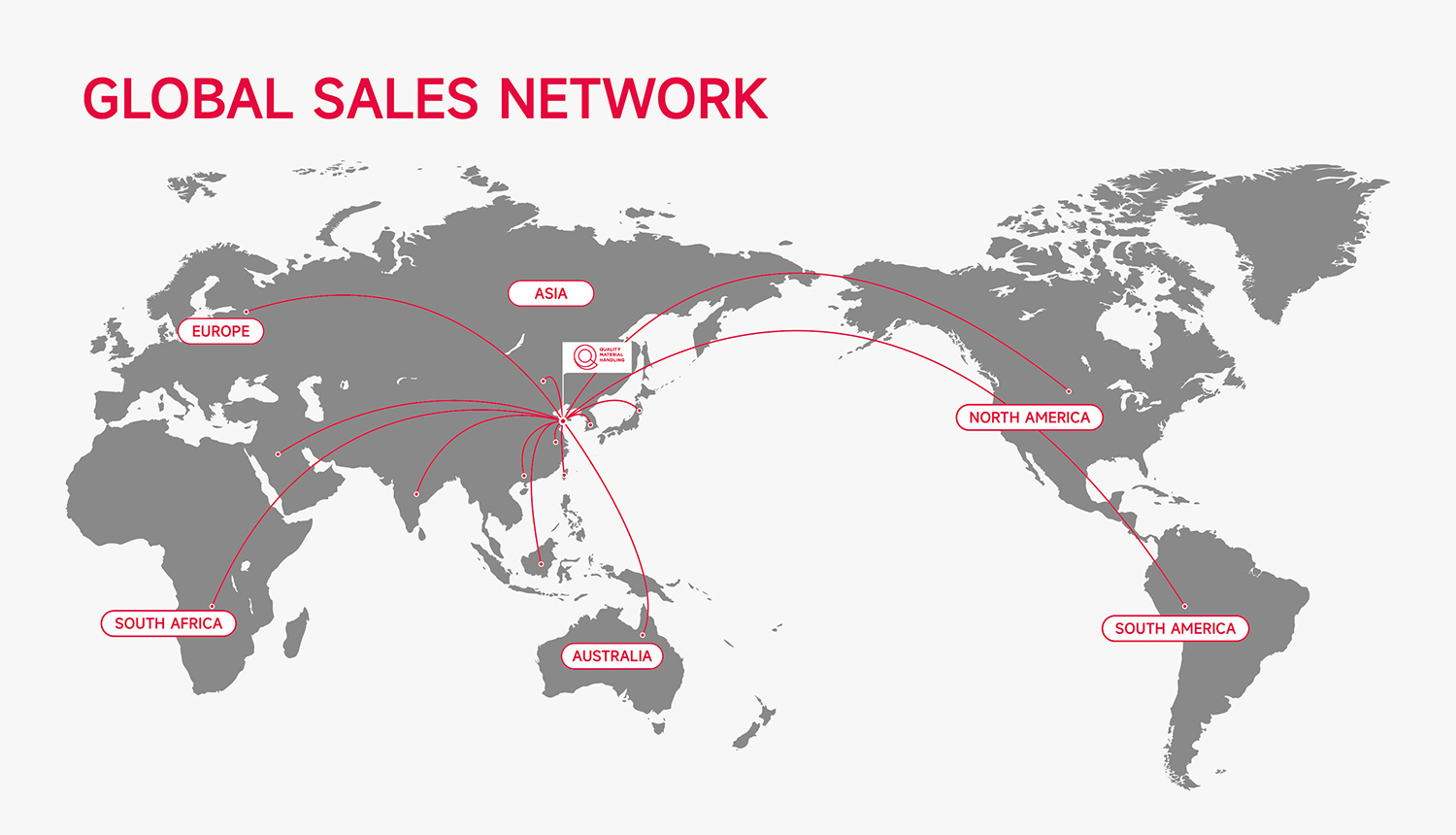

QMH products are sold in more than 50 countries and regions around the world, focusing on serving the Middle East, Southeast Asia, Europe, North America and other regions, providing innovative and efficient solutions for bulk material transportation for domestic and foreign industries such as mining, metallurgy, electric power, chemical industry, underground space, etc.