The high-quality products and services provided by the QMH technical team will make your conveying system cleaner, safer and more efficient and bring more operating benefits to users.

Keep your conveyor belt perfectly aligned and running smoothly

Consult QMH service expertsBelt misalignment in conveyor systems is a frequent problem, and even slight misalignment can cause serious problems, including equipment damage, excessive belt wear, and material spillage.

QMH provides conveyor belt misalignment solutions using products such as transfer point technology, conveyor belt positioning monitoring, and intelligent correction systems to ensure that conveyor belts are centered and running smoothly.

Transfer point technology

The irregular flow of materials at the transfer point and the strong impact force will cause the load of the receiving belt to be unbalanced, resulting in belt deviation. The QMH chute and guide trough system can effectively solve the above problems.

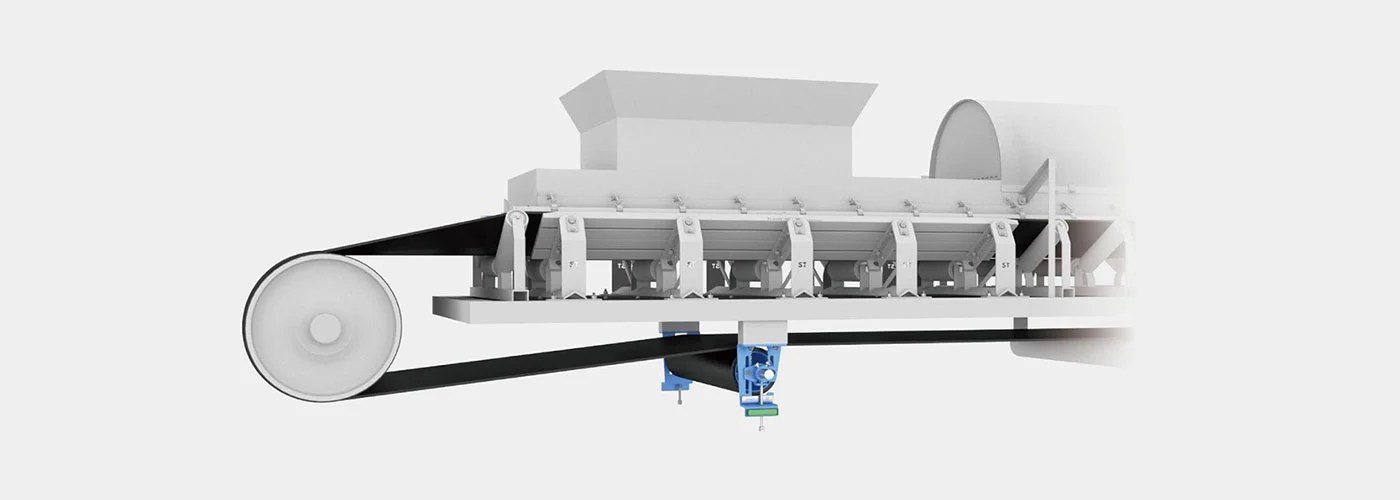

Intelligent tracking system

QMH intelligent deviation corrector, based on sensor belt running condition detection, intelligent sensor data collection and scientific deviation correction, can effectively solve the problem of correcting belt deviation after installation.

Conveyor belt positioning monitoring

The intelligent conveyor transportation system (object's location detecting system, non-destructive monitoring, positioning device, etc. ) can monitor the running status of the conveyor belt in real time, and promptly and accurately reflect abnormal conditions such as belt deviation, breakage, joint twitching, etc.

Welcome to contact QMH service experts if you want to know more about how to keep the conveyor system properly calibrated.

Preventing the return of spilled materials from the conveyor belt

Consult QMH service expertsAfter leaving the transfer point, materials often adhere to the conveyor belt and continue to fall along the return surface of the conveyor. If the return material problem is not solved, it will cause material to accumulate under the belt and accumulate on rollers, bend wheels and other components.

The accumulation of return material will not only increase operating costs, but will also shorten the service life of the belt and even cause unexpected downtime.

QMH material cleaning system and anti-stick conveyor belt can effectively solve the problem of return material.

Material cleaning system

Conveyor belt cleaner | Empty section cleaner | Cleaner scraper

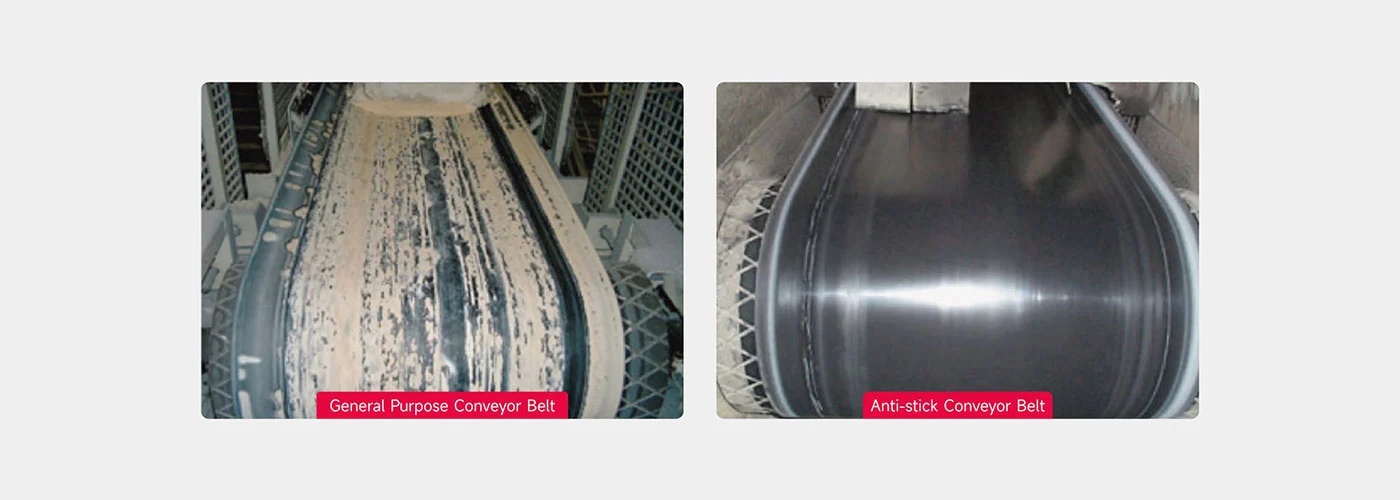

Anti-stick and easy-to-clean conveyor belt

The conveyor belt cover rubber formula contains a special composite rubber compound, which continuously releases anti-stick substances during use, has strong self-cleaning power, and can reduce the use of traditional hard metal cleaners.

Welcome to contact QMH service experts if you want to learn more about how to maintain efficient conveyor belt cleaning.

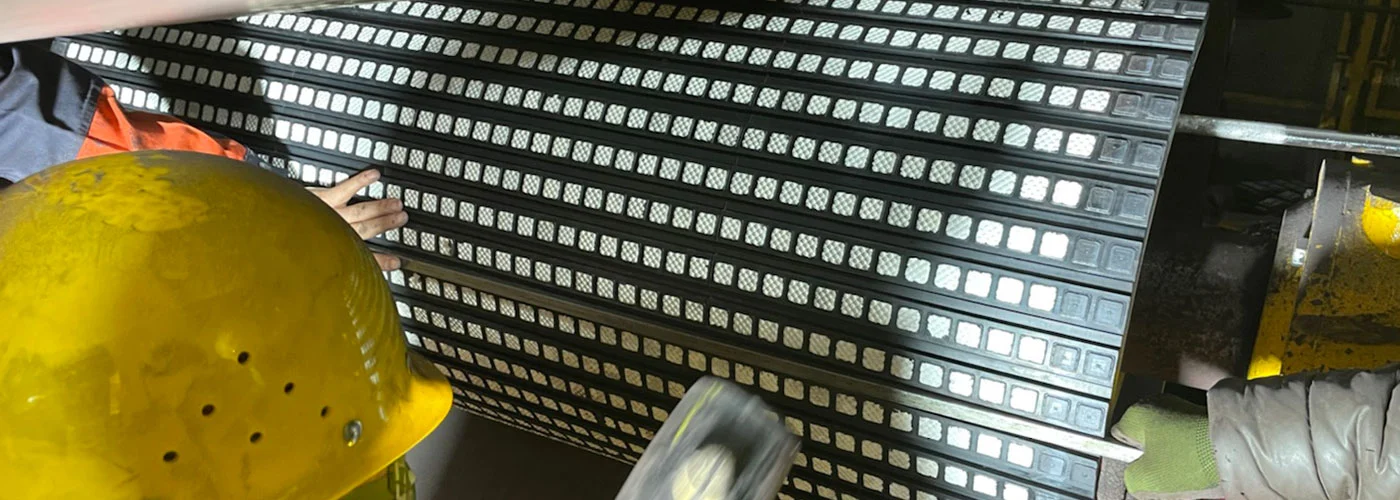

Cold vulcanized roller lagging effectively reduces slippage

Consult QMH service expertsIf the friction between the pulley and the conveyor belt is insufficient, the belt will often slip. Long-term friction and slippage of the belt will easily lead to increased surface temperature of the conveyor belt, accelerated wear and shortened service life, and even cause the conveyor belt to catch fire or cause other accidents.

To solve the problem of slippage, QMH provides cold-bonding pulley lagging service

QMH cold-bonding pulley lagging uses high-quality rubber CN layer, does not require vulcanization, and has advanced lagging technology.

Uses German GB cold bonding glue series, can be applied on-site, and is highly efficient when glued and used immediately.

Welcome to contact QMH service experts if you want to know more about how to keep the conveyor system properly calibrated.

Reduce spillage, efficient transportation, and reduce unnecessary costs

Consult QMH service expertsLeakage and spillage in the conveying system often occur at the transfer point, when the belt deviates, or when the concave section of the belt is suspended. Improper conveyor belt support, poorly sealed chutes, damaged rollers, or uneven distribution of goods can all lead to spillage. Long-term material leakage not only increases cleaning costs and pollutes the environment, but may also wrap the conveyor belt and pose a serious safety hazard.

To solve the problem of material leakage and spillage, QMH provides anti-overflow skirts, impact beds, and return belt scarpers.

Welcome to contact us if you want to know more about the material leakage and spillage.

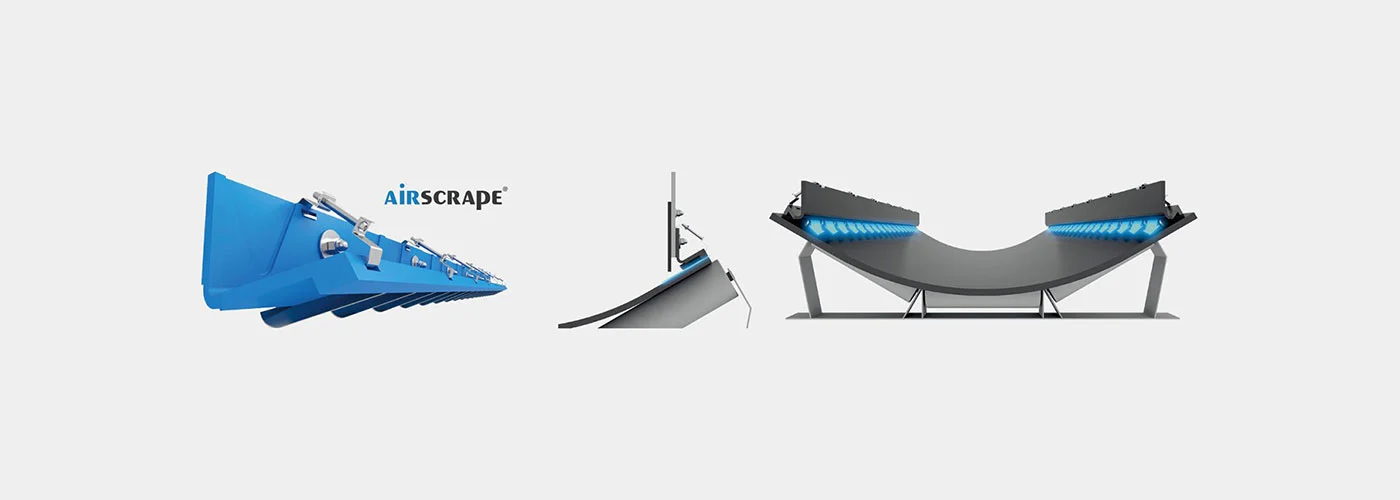

Reduce dust spillage and improve operational safety and efficiency

Consult QMH service expertsThe height difference at the conveyor belt transfer point is prone to dust escape and serious dust emission, and dust explosions are prone to occur in closed spaces. Dust accumulation can easily cause serious wear of mechanical parts of the conveyor system, and smoke and dust are harmful to health.

To solve the dust problem, QMH provides:

Airflow dust suppression system

Dust suppression at the source, dust concentration can be reduced to below 8mg/m³.

The edge seal has no contact with the belt and does not wear the belt, which can extend the service life of the belt.

The system has low energy consumption and can reduce operating and maintenance costs.

Micro-mist dust suppression system

Guide trough

Chute

Welcome to contact us if you want to know more about dust control.

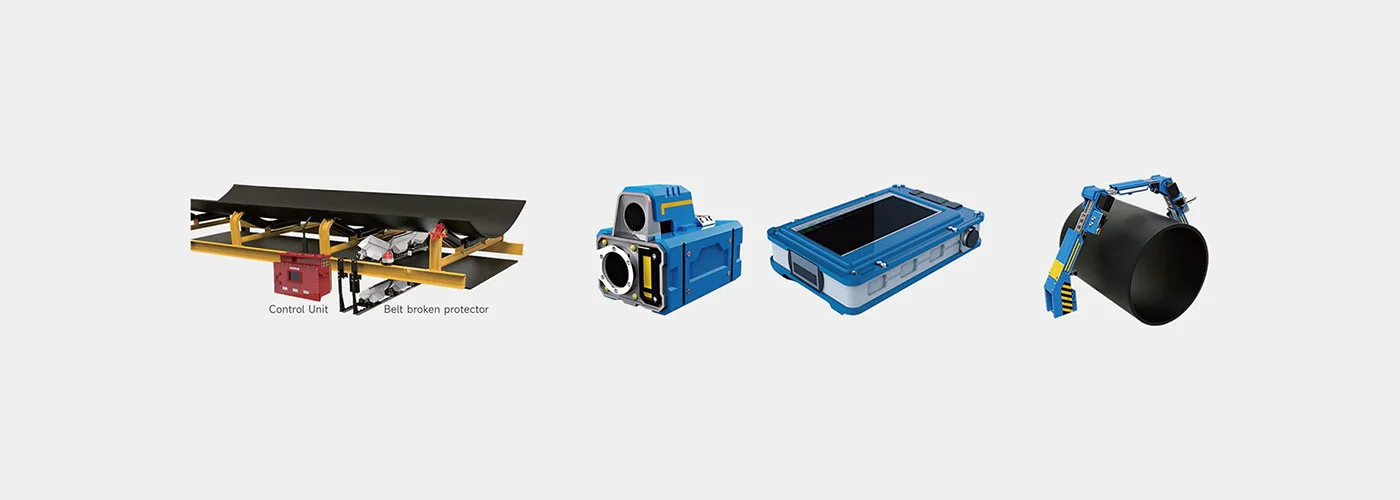

Unmanned, safe and efficient bulk material conveying ecology

Consult QMH service expertsThe QMH intelligent transportation system is based on the original belt conveyor system and introduces a variety of intelligent monitoring.

The monitoring equipment performs integrated judgment and automatically realizes linkage control with the belt conveyor according to the judgment results, realizing the reduction of manpower and unmanned belt transportation, improving the integration and safety of the belt conveyor system, realizing fault warning, and realizing unmanned, safe and efficient bulk material conveying ecology.

Safe and efficient transportation, QMH can provide intelligent conveyor transportation system

Non-destructive monitoring of conveyor belts

Stock pile monitoring system

Longitudinal tear identification system for mining conveyor belts

Flat belt monitoring system

Bucket elevator belt monitoring system

Pipe belt monitoring system

Welcome to contact us if you want to know more about the solutions of intelligent conveying.

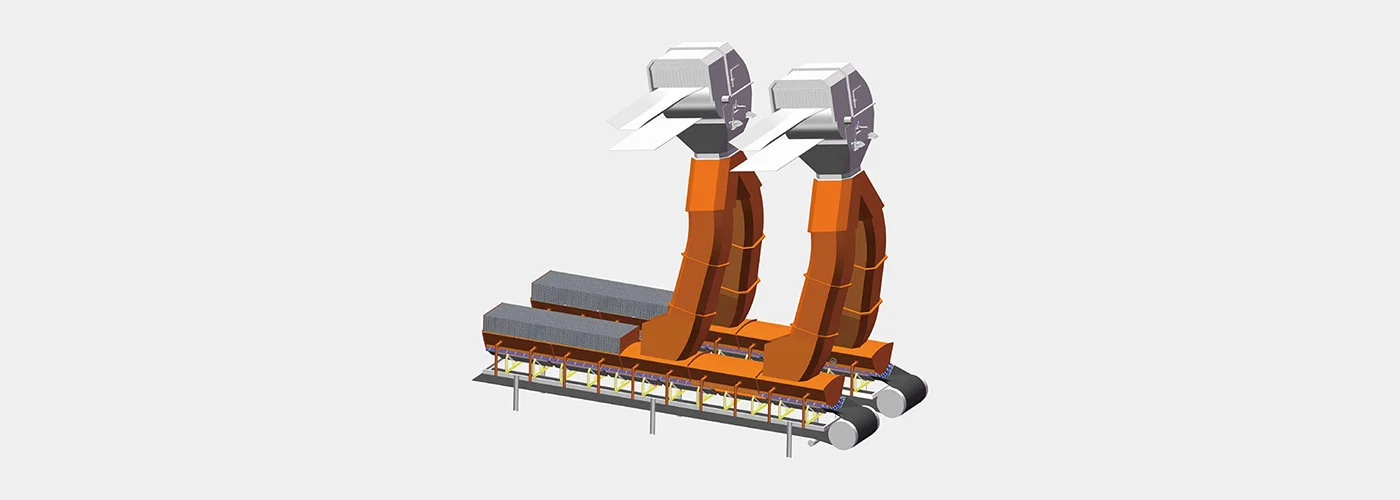

Quick installation and replacement of vertical conveying systems

Consult QMH service expertsThe installation process of the corrugated sidewall conveyor belt often faces pain points such as on-site hot vulcanized splicing, belt damage during the installation process, low installation efficiency, and high installation risks.

For the installation process, QMH can provide on-site fast installation service or technical guidance service

Nearly 20 years of experience in conveyor system installation services

Special hoisting clamps for corrugated sidewall conveyor belt

On-site hot vulcanization splicing guidance and services

Hot vulcanization splicing materials

Installation guidance and technical solutions

Welcome to contact us if you want to know more about conveyor system installation.