A well-designed conveyor system is only as good as its individual parts. From heavy-duty rollers to precision sensors, each conveyor component plays a critical role in keeping operations running smoothly. Whether you're maintaining an existing system or designing a new one, understanding these parts ensures peak performance and longevity.

1. Belts & Surfaces

- Conveyor Belts (Rubber, PVC, Modular Plastic, Wire Mesh)

- Belt Cleaners & Scrapers – Prevent material buildup

- Wear Strips – Reduce friction on sliding surfaces

2. Rollers & Pulleys

- Drive Rollers – Powered by motors to move the belt

- Idler Rollers – Support the belt’s weight and load

- Snub Pulleys – Increase belt wrap for better traction

- Take-Up Pulleys – Maintain proper belt tension

3. Motors & Drives

- AC/DC Motors – Provide movement power

- Gearboxes & Reducers – Control speed and torque

- Variable Frequency Drives (VFDs) – Adjust conveyor speed dynamically

4. Frames & Supports

- Aluminum/Steel Frames – Structural backbone of the system

- Leg Supports & Stands – Adjustable height for ergonomic loading

- Guards & Covers – Safety protection for moving parts

5. Tracking & Alignment Systems

- Belt Trackers – Auto-adjust to prevent misalignment

- Side Guides – Keep products centered

- Pivot Wheels – Correct minor belt deviations

6. Sensors & Controls

- Photoelectric Sensors – Detect product presence

- Encoder Wheels – Monitor belt speed

- Emergency Stop Switches – Instant shutdown for safety

7. Specialized Attachments

- Sidewalls & Cleats – Prevent spillage on inclines

- Magnetic Separators – Remove metal contaminants

- Dust Covers – Contain fine particles in processing

---

✔ Maximized Uptime – High-quality parts reduce breakdowns

✔ Energy Efficiency – Optimized motors and drives cut power costs

✔ Product Safety – Gentle handling prevents damage

✔ Easy Maintenance – Standardized parts simplify repairs

---

- Smart Rollers – Built-in sensors for predictive maintenance

- Self-Lubricating Bearings – Reduce manual servicing

- Quick-Release Frames – Modular designs for fast reconfiguration

- Low-Energy Motors – Cut power consumption by up to 30%

---

- Daily: Inspect belts for tears, check motor temperatures

- Weekly: Lubricate bearings, clean debris from rollers

- Monthly: Verify alignment, tighten loose fasteners

- Annually: Replace worn components, recalibrate sensors

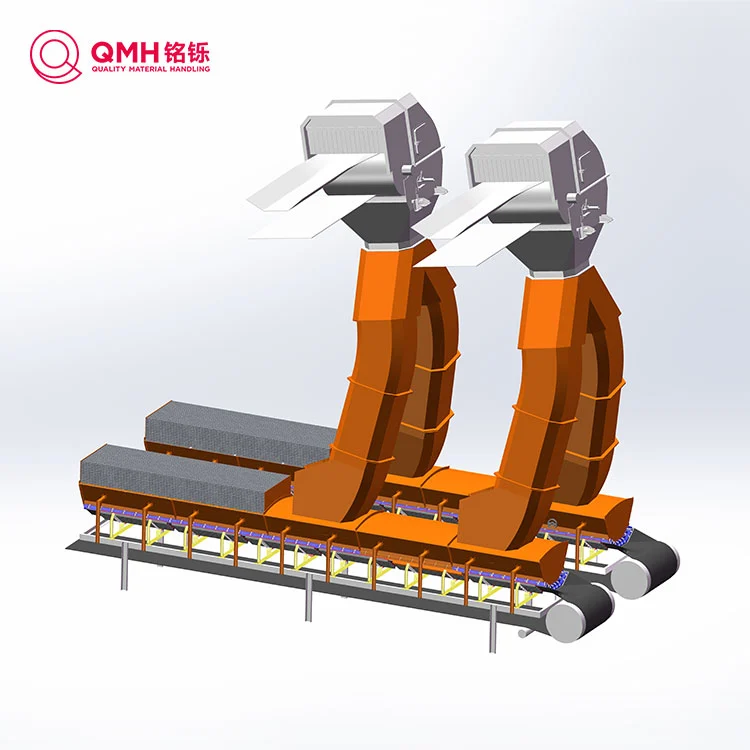

QMH-Qingdao Quality Material Handling Co., Ltd. focuses on the field of bulk material conveying, integrating product research and development, production, sales and technical services, serving customers in multiple industries such as metallurgy, mining, underground space, power plants, ports, chemicals, etc. Visit our website at https://www.qmh-service.com/ to learn more about our products. For inquiries, you can reach us at Isabella@q-mh.com.