As an important component in the belt conveyor system, the roller lagging can protect the roller from corrosion and wear of materials, extend its service life, increase the friction of the roller, avoid belt deviation, excessive adhesion of materials, and improve conveying efficiency.

QMH cold vulcanized roller lagging has solved the problem of slow lagging and poor lagging stability for many users with its advantages of high efficiency, convenience, and high bonding strength. After a large coal mining enterprise in China adopted QMH cold vulcanized roller lagging technology, the maintenance time of the conveyor belt roller was shortened by 60%, the lagging life was increased by more than 3 times, and the annual maintenance cost was reduced by 30%. The person in charge of the enterprise said: "Cold vulcanization technology not only improves equipment reliability, but also reduces downtime losses, with significant comprehensive benefits."

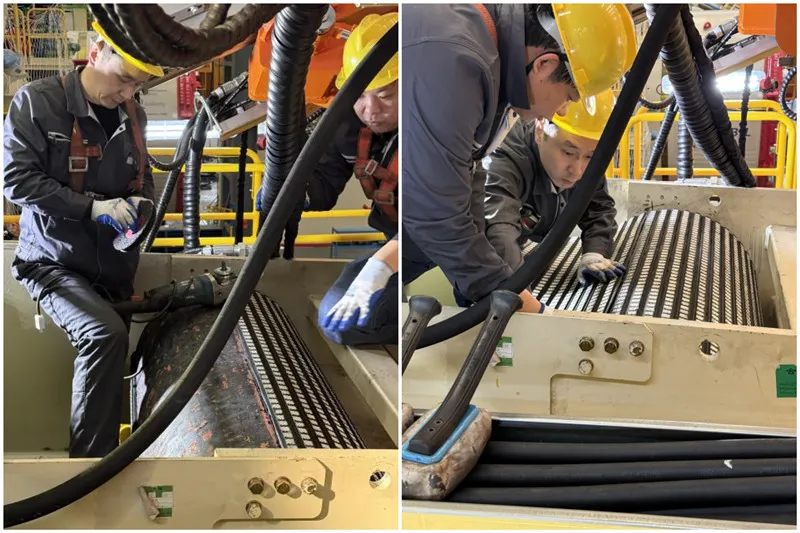

Efficient and convenient, saving downtime

Compared with the traditional hot vulcanization process, cold vulcanized lagging can be directly constructed on site/conveyor, greatly shortening downtime and significantly improving production efficiency.

Excellent bonding strength and wear resistance

QMH CB2000 cold vulcanized adhesive has extremely strong bonding strength, with a bonding strength of 9-12N/mm

Environmental protection and energy saving, reducing overall costs

QMH's special CN cold adhesive layer, no need for vulcanization, no grinding, more environmentally friendly, in line with the trend of green manufacturing

Stable performance and long service life

The service life is about 4-6 times that of hot vulcanization