In industrial production, wear protection and pulley lagging technology have become the core protection means in the fields of material transportation, heavy processing, etc. by extending the life of equipment and improving operating efficiency. Its application scenarios cover multiple industries, providing customized solutions for different equipment wear pain points.

The pulley lagging of belt conveyor is the most typical application. It uses rubber material (hardness 60-80 Shore A) to wrap the surface of the metal roller, and the friction coefficient is increased to more than 0.8, which reduces the belt slippage and improves the conveying efficiency by 15%-20%. In the coal mining industry, the service life of the roller after coating is extended from 3 months to 18 months, reducing 3-4 replacement downtime per year.

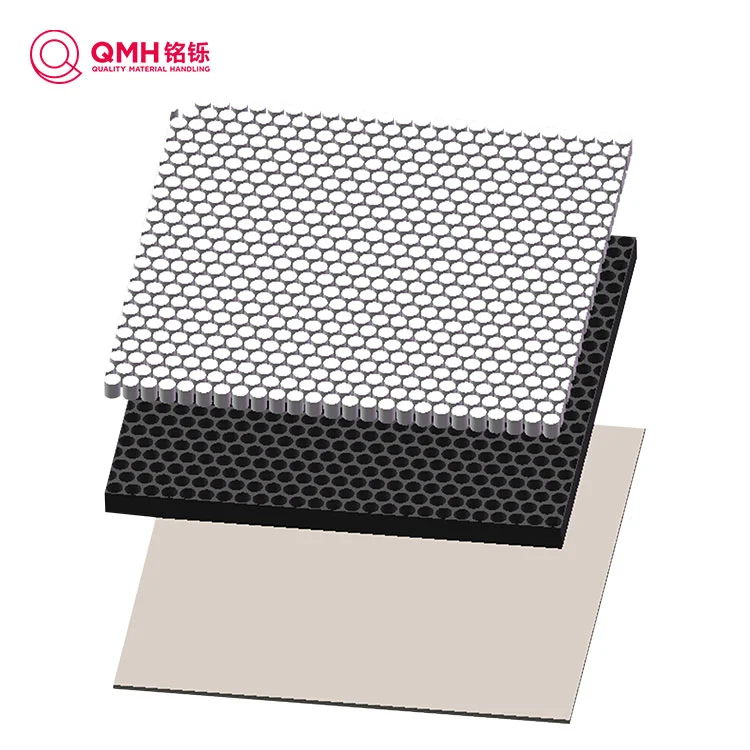

The wear protection of the conveyor belt is achieved by covering the surface with a polyurethane coating (thickness 3-5mm), with a tear strength of 30N/mm. When conveying sharp materials such as iron ore and granite, the belt wear rate is reduced by 70%, and the service life of a single belt is extended from 1 year to 2-3 years.

The lining of the mining crusher adopts high chromium cast iron wear protection (hardness ≥ HRC60) and impact toughness ≥ 15J/cm². When crushing hard rocks such as basalt, the lining replacement cycle is extended from 15 days to 90 days, and the annual cost of accessories for a single machine is saved by more than 100,000 yuan. Wear-resistant rubber strips (Shore hardness 75A) are installed on the edge of the vibrating screen to reduce edge tearing caused by material impact and increase the life of the screen by 3 times.

The inner wall of the ball mill is protected by alumina ceramic patches (wear resistance is 20 times that of steel) and bonded with high-temperature resin. When grinding cement clinker, the inner wall wear is controlled within 0.1mm/month, and the equipment maintenance cycle is extended from 2 months to 1 year.

The grab blade of the port unloader adopts a bimetallic composite material (low-carbon steel matrix + high-chromium alloy layer) with a hardness of HRC58-62. When grabbing iron ore and coal, the wear rate of the blade is reduced by 60%, and the service life of a single set of grabs is extended from 800 hours to 2000 hours.

The drum rubber coating of the stacker is flame-retardant rubber (in accordance with MT113 standard). In the hot and rainy port environment, it can not only prevent materials from sticking to the drum but also resist ultraviolet aging. The service life of the rubber coating is more than 2 years, which is 1 time longer than that of ordinary rubber.

The inner wall of the compression chamber of the garbage compression truck is made of wear-resistant steel plate (hardness 400-500HBW), and the surface is shot blasted to increase the friction coefficient. When compressing construction waste and metal waste, the wear of the cavity is reduced by 80%, and the equipment overhaul cycle is extended from 1 year to 3 years.

The roller brush shaft of the sweeper is protected against wear by spraying tungsten carbide coating (thickness 0.1-0.3mm), and the bonding strength of the coating is ≥80MPa. When sweeping asphalt pavement, the rust and wear problems of shaft parts are significantly improved, and the replacement frequency is reduced by 60%.

The guide rails of CNC machine tools are protected against wear by plastic coating (PTFE + bronze powder composite material), with a friction coefficient as low as 0.04-0.06. When moving at high speed (30m/min), the guide rail wear is ≤0.01mm/1000 hours, ensuring the long-term stability of the machining accuracy (±0.005mm).

The piston rod of the hydraulic cylinder is protected against wear by chrome plating (coating thickness 0.05-0.1mm), with a surface roughness Ra≤0.2μm. In mining machinery and engineering machinery, the corrosion and scratch resistance are increased by 5 times, and the cylinder leakage failure rate is reduced by 90%.

Through material science and process innovation, wear protection and pulley lagging technology provide precise protection for different types of wear (abrasive wear, adhesive wear, fatigue wear), while improving equipment reliability and reducing overall operating costs, becoming a key technical means for reducing costs and increasing efficiency in modern industry.