Diamond pulley laggings are commonly used for most applications for conveyor pulleys, offering sufficient friction and longevity under normal operating conditions. However, when would you opt for ceramic pulley laggings?

Diamond pulley laggings can withstand most harsh working conditions. However, if the environment has a high content and the material being transported is highly abrasive, the self-cleaning capacity of diamond pulley laggings will be in sufficient, leading to reduced friction and belt slippage. In this scenario, ceramic rubber plates are the recommended choice.

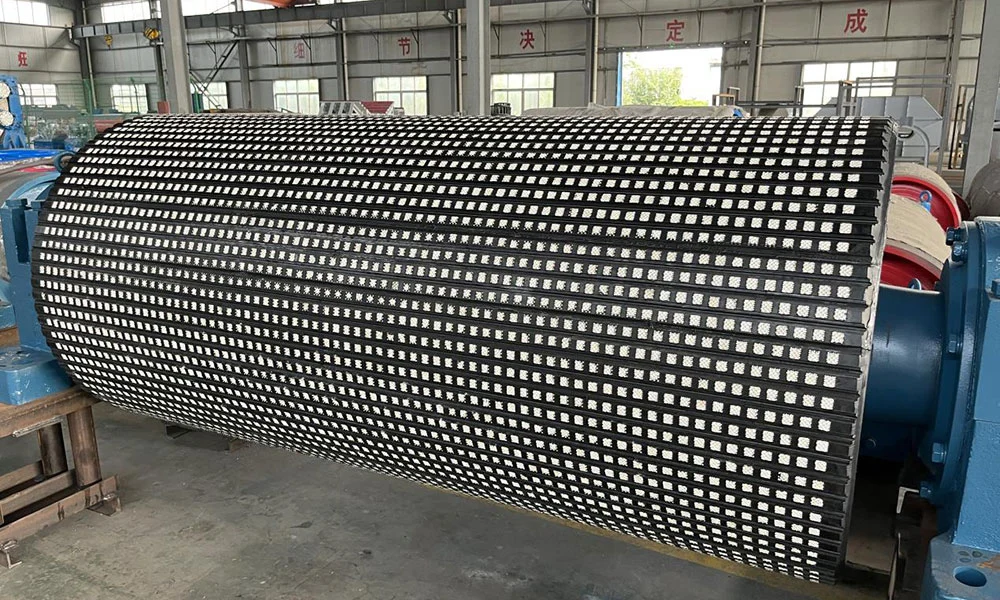

QMH ceramic pulley laggings are ideal for transporting muddy, wet, and highly abrasive material. They boast exceptional wear resistance and a long service life (8-10 times longer than conventional rubber under the same working conditions). They effectively prevent belt slippage. Ceramic pulley laggings have deeper grooves than diamond pulley laggings, ensuring excellent drainage and mud removal, keeping the surface clean and reducing belt tension under the same load, thereby extending the belt’s lifespan.