In heavy-duty conveying sites such as mines and docks, Pulley Lagging technology is silently guarding the stability of material transportation. This process of coating a special rubber layer on the surface of the metal drum effectively solves annoying problems such as belt slippage and deviation.

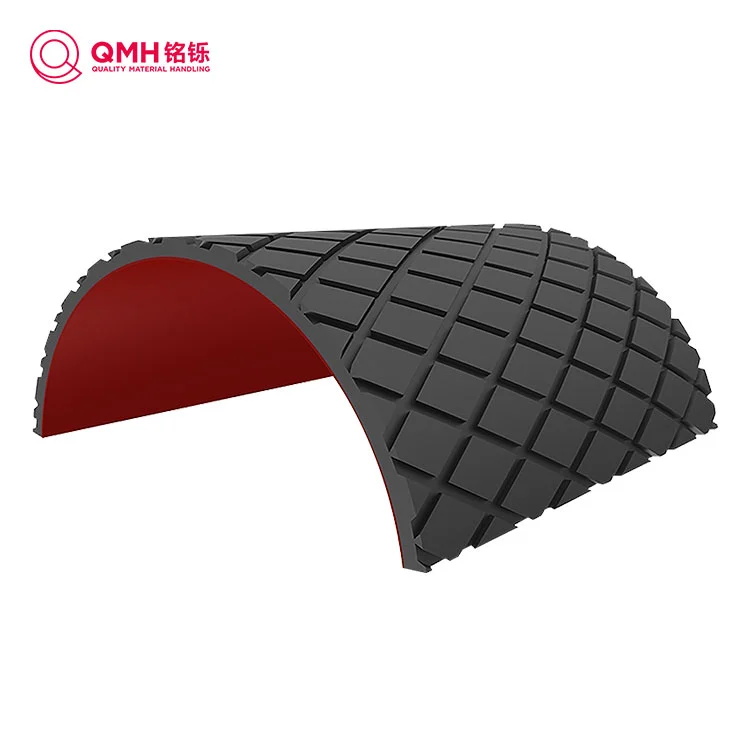

The key lies in the triple protection brought by the rubber layer: first, the high friction coefficient ensures that the belt and the drum fit tightly to prevent slippage; second, the buffering effect reduces the impact damage to the belt; finally, the anti-corrosion properties extend the life of the metal drum. Modern encapsulation technology can also choose different rubber formulas according to working conditions, such as wear-resistant, oil-resistant or anti-static.

High-quality encapsulation treatment must achieve three goals:

1. The bonding strength between rubber and metal drum exceeds 15N/mm

2. The surface groove design improves the drainage and mud discharge capacity

3. Dynamic balance test ensures smooth operation

From the main shaft of coal mines to the port loading system, the rubber-encapsulated pulley has become a key component of conveying equipment with its reliable performance. This seemingly simple rubber wrapping is actually the secret weapon that ensures the stable operation of the entire conveying system.

QMH-Qingdao Quality Material Handling Co., Ltd. focuses on the field of bulk material conveying, integrating product research and development, production, sales and technical services, serving customers in multiple industries such as metallurgy, mining, underground space, power plants, ports, chemicals, etc. Visit our website at https://www.qmh-service.com/ to learn more about our products. For inquiries, you can reach us at Isabella@q-mh.com.