In heavy industrial sites such as mines and cement plants, equipment wear is the number one killer that causes downtime and maintenance. Wear Protection technology is like putting a layer of invisible armor on the equipment, using professional materials and methods to resist wear and tear, and greatly extending the service life of key components.

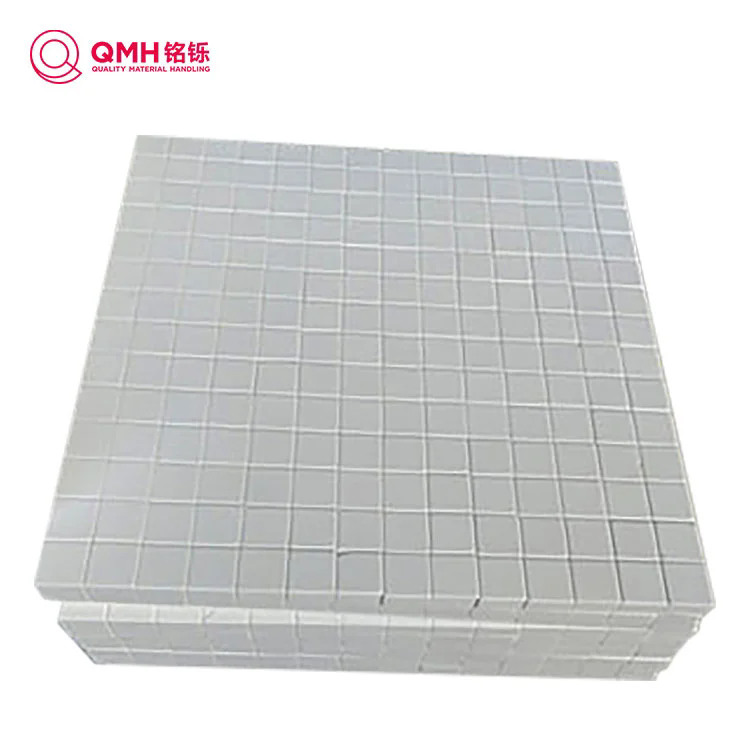

The key lies in "prescribing the right medicine for the right disease". Engineers have developed a variety of solutions for different types of wear: for impact wear, high manganese steel linings are used to absorb energy; for sliding wear, chromium carbide cladding layers are used to increase surface hardness; in powder scouring areas, ceramic linings are installed to form a protective barrier.

There are three major development trends in modern Wear Protection technology:

1. Composite protective materials take into account both hardness and toughness

2. Modular design facilitates local replacement

3. Intelligent monitoring and early warning of wear

From crusher jaws to feed pipelines, from fan impellers to pump body flow channels, Wear Protection is providing all-round protection for industrial equipment. This invisible engineering art uses scientific and technological means to extend the life of equipment by 3-5 times, saving companies a lot of maintenance costs and downtime losses.

QMH-Qingdao Quality Material Handling Co., Ltd. focuses on the field of bulk material conveying, integrating product research and development, production, sales and technical services, serving customers in multiple industries such as metallurgy, mining, underground space, power plants, ports, chemicals, etc. Visit our website at https://www.qmh-service.com/ to learn more about our products. For inquiries, you can reach us at Isabella@q-mh.com.