As the global dual-carbon strategy progresses, more and more companies are paying attention to energy conservation, emission reduction, and environmental protection in their production processes.

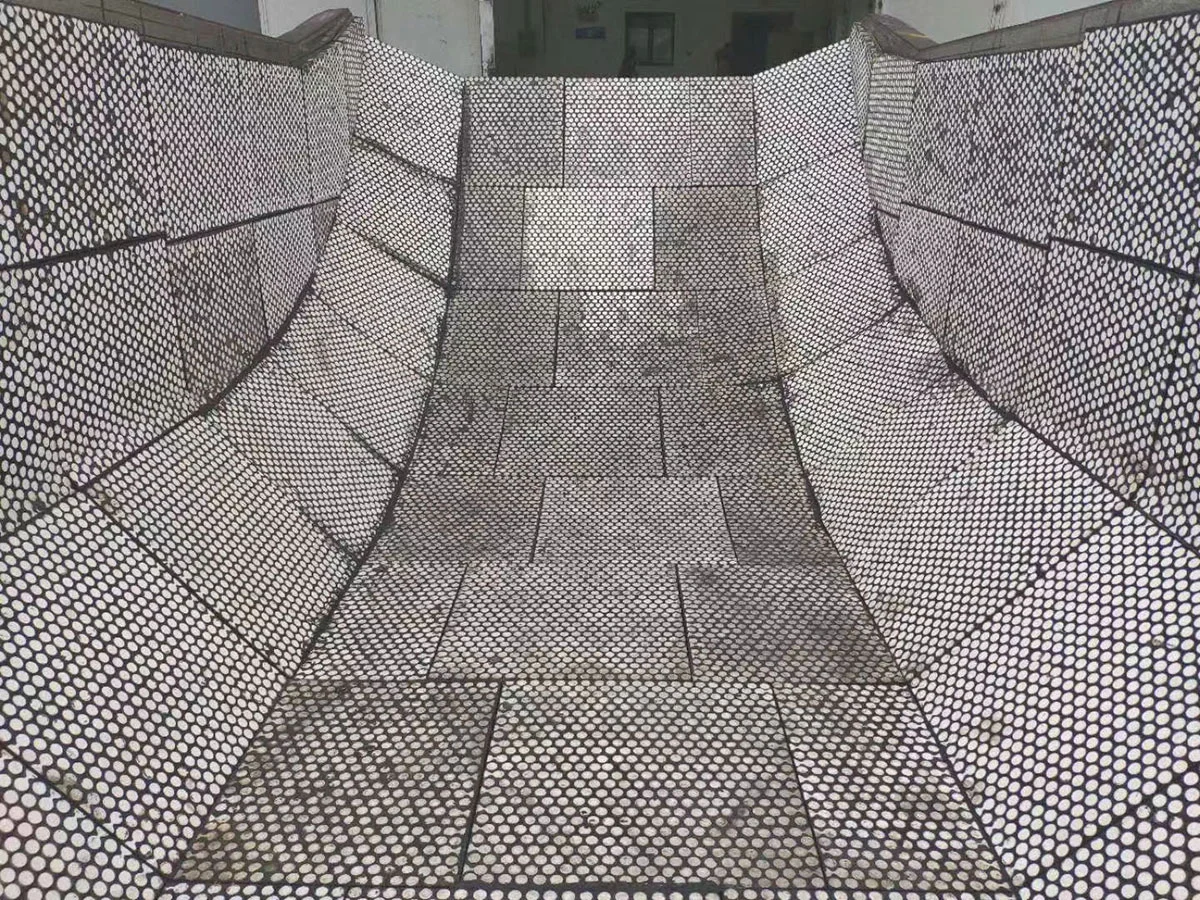

The role of chutes in bulk material handling systems can’t be overlooked. Companies are also setting higher requirements for the materials used in chutes.

Wear-resistant ceramic materials have become a popular choice for chutes nowadays, and they offer the following advantages:

Excellent wear resistant: Wear-resistant ceramics posses outstanding wear resistance. Therefore, chutes made of wear-resistant ceramics exhibit strong wear resistance and good corrosion resistance, extending their service life and reducing operating costs for companies.

Superior impact resistance: Wear-resistant ceramic chutes demonstrate excellent impact resistance. Even under intense impact, they are unlikely to crack, ensuring safe operation and maintaining the stability of the processing.

Low pollution: Compared to other chute materials, wear-resistant ceramics have low energy consumption and minimal environmental pollution, making them an eco-friendly choice for many companies.

Easy to repair: During use, damage to chutes is unavoidable. Chutes made of other materials can’t be maintained or repaired back to their original condition after maintenance. Wear-resistant ceramic chutes can prevent this situation because of their high hardness and resistance to damage from external objects. Even if minor damage occurs, it can be repaired with ceramic repair agents.

Lightweight and durable: Compared to other chute materials, wear-resistant ceramic materials are lighter in weight, which makes the system need less during transportation. At the same time, wear-resistant ceramic materials have very high toughness, can resist high temperature, high pressure and other harsh environments, and have a longer service life