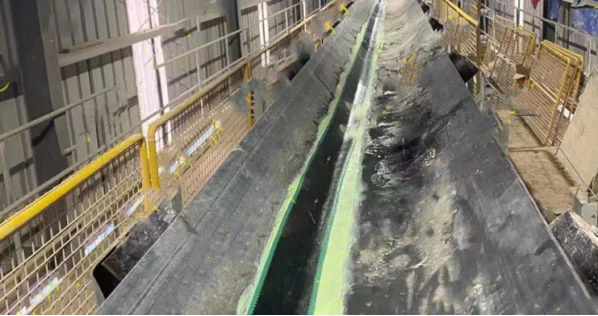

When the conveyor belt is damaged, it should be repaired in time to reduce the loss. QMH recommends three repair methods: hot vulcanized slicing, cold vulcanized slicing, cold adhesive repair.

1. Hot vulcanization joint

With the vulcanizer, the damaged part can be re-vulcanized in a relatively short time. This is very useful for some slightly worn parts and can quickly restore the performance of the conveyor belt, but this treatment requires the use of vulcanization equipment, and the time cost is high, so it is not recommended for large-area repair.

2. Cold vulcanization repair

Repair conveyor belts with a fast and effective material, such as QMH-518 Quick Repair Glue. This method is faster, the wear resistance after repair will be greatly enhanced, and the use of cold treatment can maintain the strength and elongation of the material, while reducing the viscosity for large area application.

3. Cold bonding repair

Repair with a patch strip. QMH Repair Strip have semi-vulcanized layer without need to polish, and high tensile strength, excellent wear resistance, simple operation, can be quickly repaired without waiting. It is commonly used to repair long distance scratches, scratches and edge wear on conveyor belts.