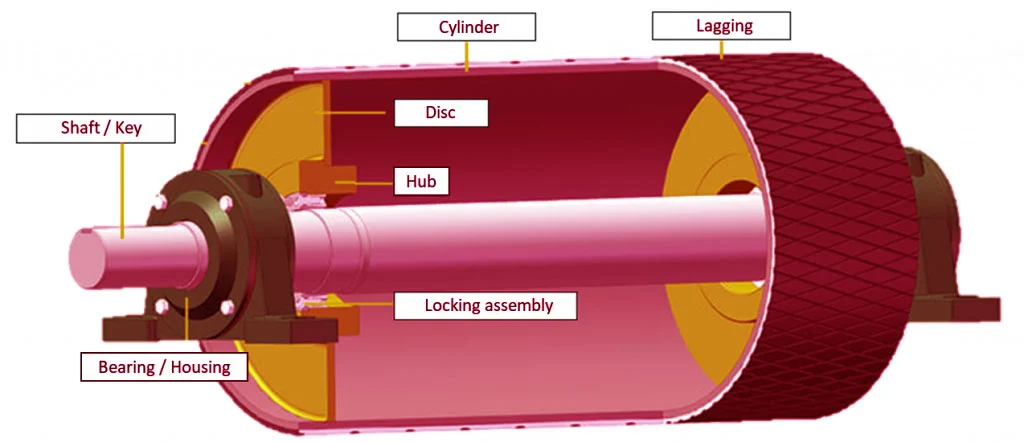

The Drive Pulleys are designed for use on conveyor belt systems to drive/redirect the conveyor belt on its system through tension that is created. All conveyor systems will include at least two pulleys: a head pulley and a tail pulley. The additional pulleys are dependent on the application requirements.These additional pulleys include snub, drive, bend and take-up pulleys. QMH is a supplier of all conveyor belt pulley variations.QMH pulleys are integral components in conveyor systems, serving to guide and drive the belt, ensuring smooth and efficient operation. Pulleys can be classified based on their functions and roles within the system. QMH selects the right materials and design features, such as reinforced shafts or additional lagging, to enhance the pulley’s performance and durability.

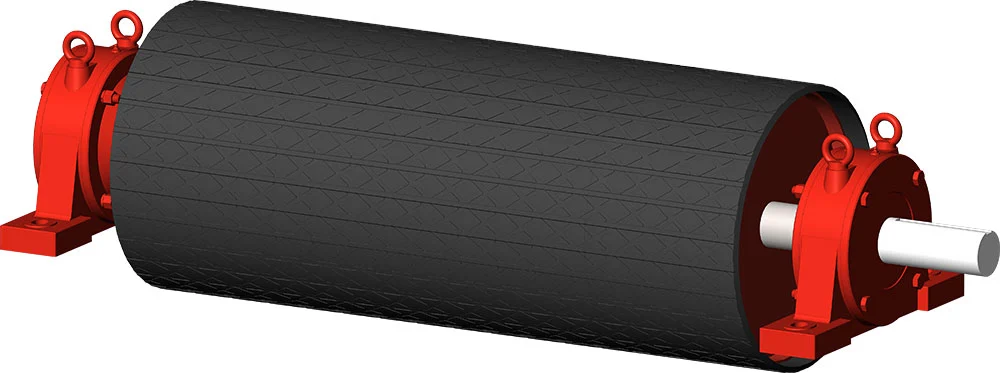

Send InquiryDrive Pulley is connected to the power source and provides the primary driving force for the conveyor belt. It's usually located at the head of the conveyor and is the main component responsible for moving the belt.

Typically located at the discharge point of a conveyor belt system (by the motor) & drives the conveyor belt. The drive pulleys are normally larger in diameter than others, and are typically lagged with diamond pulley lagging or ceramic pulley lagging to increase traction, thus reducing belt spillage as well as the belt tension. The drive pulley is the main component that transmits traction to the conveyor belt. When the environment is humid, large power, and slippery, pulley lagging should be used. The rubber pulley lagging is divided into flat rubber pulley lagging, herring bone rubber surface (suitable for one-way operation), diamond pulley lagging and Ceramic pulley lagging (suitable for two-way operation), etc.

1. Drum Body Material: Commonly uses high-quality carbon steel which has good mechanical properties and weld-ability.

2. Shaft Material: Usually made of 45# steel, subjected to tempering to enhance its strength and wear resistance.

3. Bearings: Renowned brand bearings are selected to ensure smooth operation and long service life of the drum.

In summary, QMH ensure high-quality, reliable products through strict material selection, advanced manufacturing processes, and comprehensive quality control to meet various heavy-duty material transportation needs.

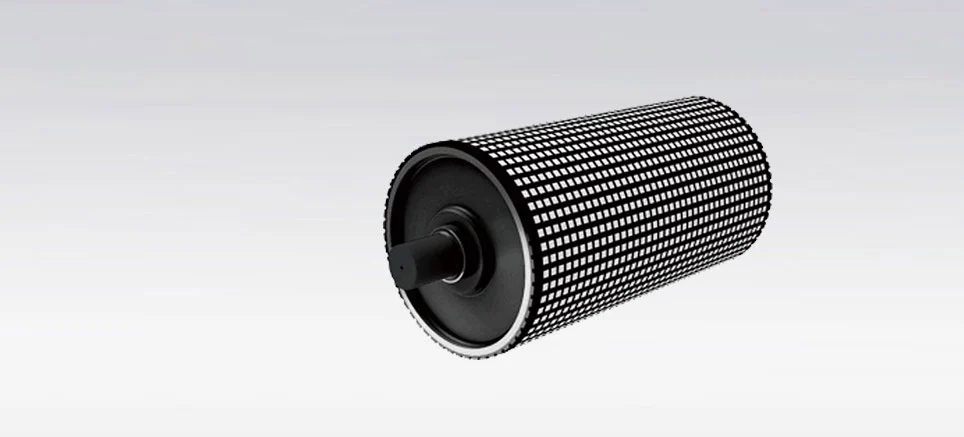

QMH Drive Pulley with Ceramic lagging

The quality of drive pulleys is a critical factor in the overall performance and efficiency of conveyor systems. QMH High-quality drive pulleys ensure the longevity and reliability of the system, minimizing downtime and maintenance costs. Here are the impacts of using high-quality QMH pulleys and following are five examples to illustrate their importance.

1. Enhance lifespan of the conveyor system

QMH High-quality pulleys significantly enhance the lifespan of a conveyor system. These pulleys are designed and manufactured to withstand the rigors of continuous operation, reducing the tear and wear on the conveyor belt and other components. By using superior materials and advanced manufacturing techniques, belt conveyor drum pulley QMH produces pulleys that maintain their structural integrity over extended periods, even in demanding environments.

2. Reduced Maintenance Costs

Investing in high-quality pulleys can lead to significant reductions in maintenance costs. Inferior pulleys are prone to frequent breakdowns and require regular maintenance to keep the conveyor system running smoothly. QMH High-quality pulleys, on the other hand, are designed for durability and reliability, resulting in fewer maintenance interventions and associated costs.

3. Improved Performance

The performance of a conveyor system is heavily dependent on the quality of its pulleys. QMH High-quality pulleys ensure smooth and efficient operation, reducing energy consumption and enhancing the overall productivity of the system. Belt conveyor drum pulley QMH focus on optimizing pulley designs to maximize performance and efficiency.

4. Enhanced Safety

Safety is a paramount concern in any industrial setting. QMH High-quality pulleys contribute to safer conveyor operations by reducing the risk of unexpected failures and accidents. QMH adhere to stringent quality standards to produce pulleys that meet or exceed safety regulations.

5. Long-Term Cost Savings

While QMH high-quality pulleys may have a higher initial cost, they offer substantial long-term cost savings. The reduced need for maintenance, fewer replacements, and improved efficiency contribute to lower overall operational expenses. QMH provide products that offer excellent value for money through their longevity and reliability.

Selecting the right drive pulley is crucial for the efficient and reliable operation of your conveyor system. QMH offer a wide range of pulleys designed to meet specific needs and applications. Understanding the key factors to consider when selecting a drum pulley QMH can help you make an informed decision that enhances the performance and longevity of your conveyor system.

Application Fields

Drive/Head pulleys are widely used in industries that require the transportation of bulk materials, such as mining, ports, power plants, cement plants, and steel mills. Specific applications include:

Mining Transportation: Used for conveying ores in coal mines, iron mines, copper mines, etc. In mining operations, the head pulley is subjected to extreme conditions, including heavy loads and abrasive materials. QMH High-quality head pulleys are designed to withstand these harsh conditions, ensuring consistent and reliable performance. The head pulley's durability is essential to minimize downtime and maintain productivity in such demanding environments.

Port Terminals: Used for loading and transporting bulk materials like coal, ores, and grain.

Power Plants: Used for conveying coal and ash. Precision in the drawings ensures that the pulleys are robust enough to handle the load while maintaining smooth operation.

Cement Plants: Used for transporting raw materials such as limestone and clay. QMH well-designed head/drive pulley ensures smooth and efficient movement, reducing the risk of belt slippage and maintaining a steady production flow.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.