QMH Steel cord conveyor belts are widely used for longer conveyors, higher loads, and more complex routing in coal, mining, port, metallurgy, power plant and chemical industries for conveying of lumps, granules, powders,etc. QMH Steel cord conveyor belt is a versatile and robust conveyor belt that has significantly impacted various industries. Its high strength, wear resistance, corrosion resistance, and heat resistance make it an ideal choice for handling heavy loads and conveying materials over long distances.

Send InquiryQMH Steel cord conveyor belts are with high strength: When the belt operating tension has to be higher than 2500 KN/m, belts reinforced with steel cords are the only alternative; Steel cord conveyor belts designed by QMH rates up to 10000 KN/m. QMH Steel cord belts are also an economical alternative to fabric belts with ratings between 1000 KN/m and 2500 KN/m.

low elongation

excellent adhesion

high tensile strength

good troughability

lower operating cost

uniform tension of steel cord

lightweight and energy-saving

small pulley diameter required

X-ray inspection available.

Low Rolling-resistant

Flame-resistant

Heat-resistant

Cold-resistant

Normal abrasion-resistant

High abrasion-resistant

Acid & Alkali-resistant

Oil-resistant

Anti-sticky

1. High Strength and Load Capacity:

The steel wire rope tensile body enables the belt to withstand high tensile forces, making it suitable for conveying heavy loads over long distances.

2. Long Service Life:

The rubber and steel wire rope have high bonding strength, alleviating the mutual shear and twisting of the strands. This, combined with excellent dynamic fatigue resistance, gives the product a long service life.

3. Good Flexibility and Resistance:

The belt has good flexibility and resistance to bending, impact, and tearing, making it suitable for conveying materials under harsh conditions.

4. Wide Range of Applications:

Steel cord conveyor belts can be used in various industries such as coal mining, metallurgy, ports, electric power, and chemical industries. They are ideal for conveying materials under high-strength, long-distance, and large-volume conditions.

1. Ordinary Structure Steel Cord Conveyor Belt:

Suitable for general conveying applications in industries such as coal mining and metallurgy.

2. Anti-Tear (Transversely Reinforced) Steel Cord Conveyor Belt:

Reinforced with additional layers to enhance tear resistance, making it suitable for conveying materials with sharp edges or high tear strength requirements.

3. Embedded Coil Anti-Tear Type:

Incorporates a phase shift sensor (coil) buried between the core rubber and the lower covering layer. This type of belt has microcomputer programming control, which alarms and stops automatically when the conveyor belt is detected to be torn.

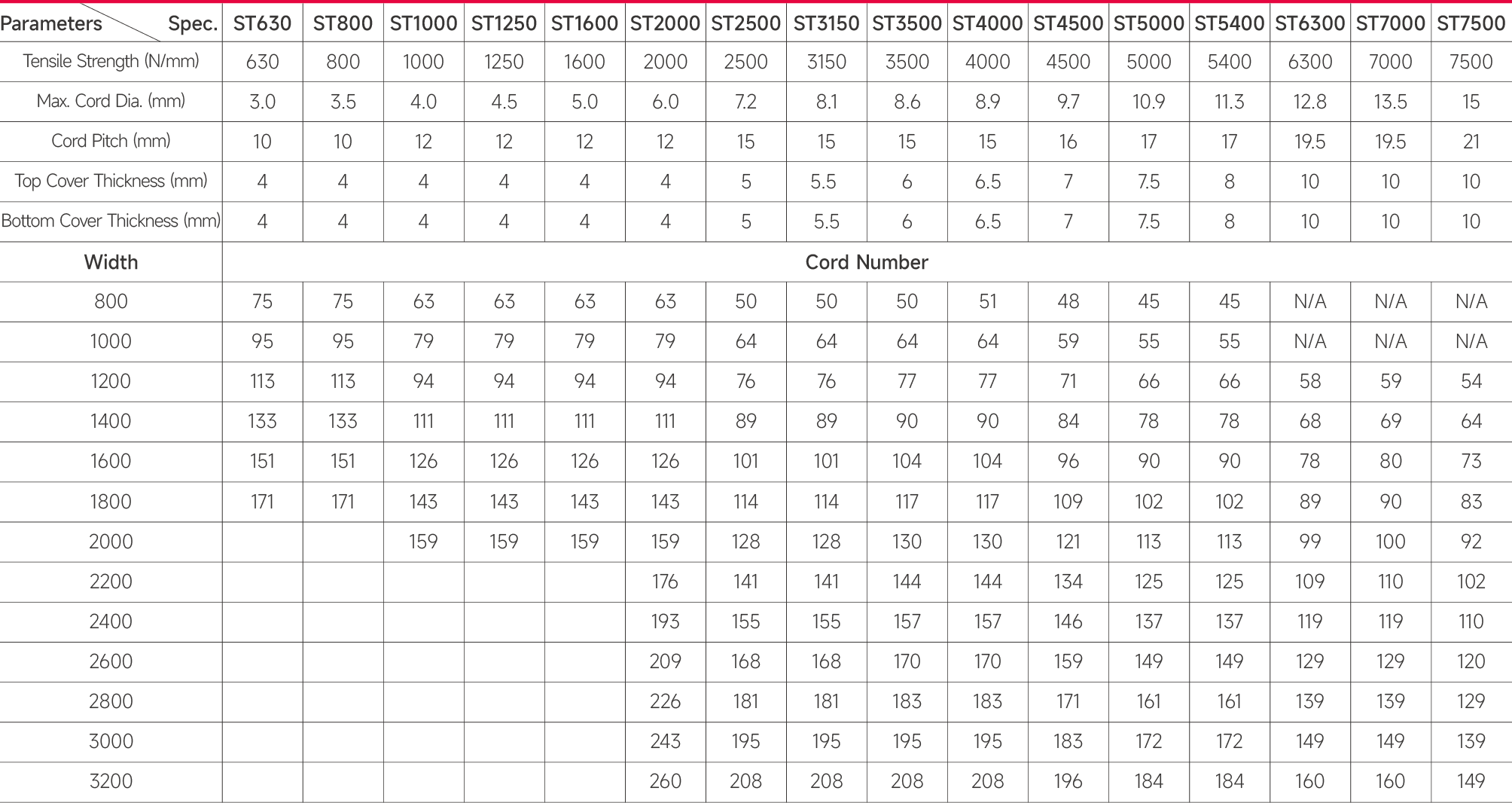

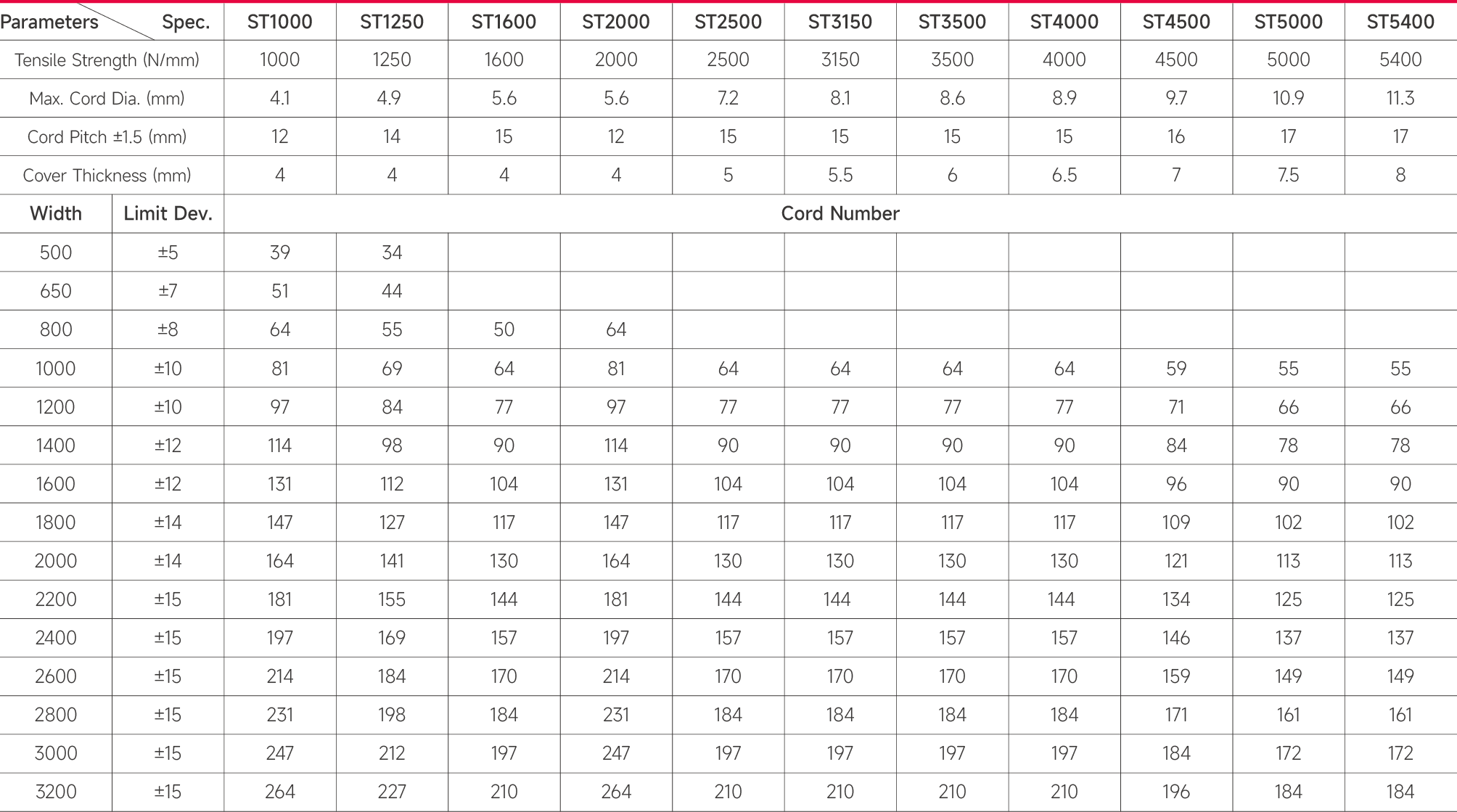

The technical parameters of steel cord conveyor belts vary depending on the specific application and manufacturer. Some key parameters include band strength specifications, longitudinal tensile strength, nominal diameter of wire rope, wire rope spacing, cover thickness, and width. These parameters can be customized to meet the specific requirements of the conveying system.

In conclusion, steel cord conveyor belts are an essential component in many industrial applications. Their high strength, load capacity, long service life, and wide range of applications make them an ideal choice for conveying materials under harsh conditions.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.