QMH Aramid conveyor belts are a type of high-performance industrial conveyor belts that utilize aramid fibers as their primary reinforcement material. Aramid fibers, also known as aromatic polyamide fibers, are a class of synthetic fibers characterized by their exceptional strength, modulus, and heat resistance. These fibers are widely used in various industries due to their superior properties.

Send InquiryQMH Aramid Conveyor belts are essential in industries such as mining, ports, metallurgy, cement production, and power generation. They are used for continuous material handling and transportation over long distances. Aramid conveyor belts are particularly suited for these applications due to their lightweight, high strength, and low elongation properties.

QMH Aramid conveyor belts combine high-strength, light reinforcement with a variety of cover materials to enable them for a broad range of applications.

·Low energy consumption

·Excellent impact resistance

·High-temperature resistant

·Flame-retardant

·Corrosion-resistant

·Long service life

QMH Aramid Conveyor Belt is a type of conveyor belt that incorporates longitudinally extending reinforcements or traction bearers made of aromatic polyamide (aramid) fibers. Aramid fibers are known for their high tensile strength, heat resistance, and excellent durability, making them ideal for use in conveyor belts that need to withstand heavy loads and operate in harsh environments.

1. High Tensile Strength: The aramid fibers provide the conveyor belt with exceptional tensile strength, allowing it to support heavy loads without breaking or deforming.

2. Heat Resistance: Aramid fibers are resistant to high temperatures, making the conveyor belt suitable for use in environments where heat is a concern.

3. Durability: The combination of aramid fibers and elastomeric materials results in a conveyor belt that is highly durable and resistant to wear and tear.

4. Cut and Abrasion Resistance: The aramid fibers also contribute to the belt's resistance to cuts and abrasions, extending its lifespan and reducing the need for frequent replacements.

QMH Aramid Conveyor Belts are widely used in various industries, including mining, energy, and manufacturing. They are particularly suited for applications where the conveyor belt needs to transport heavy, abrasive, or hot materials over long distances.

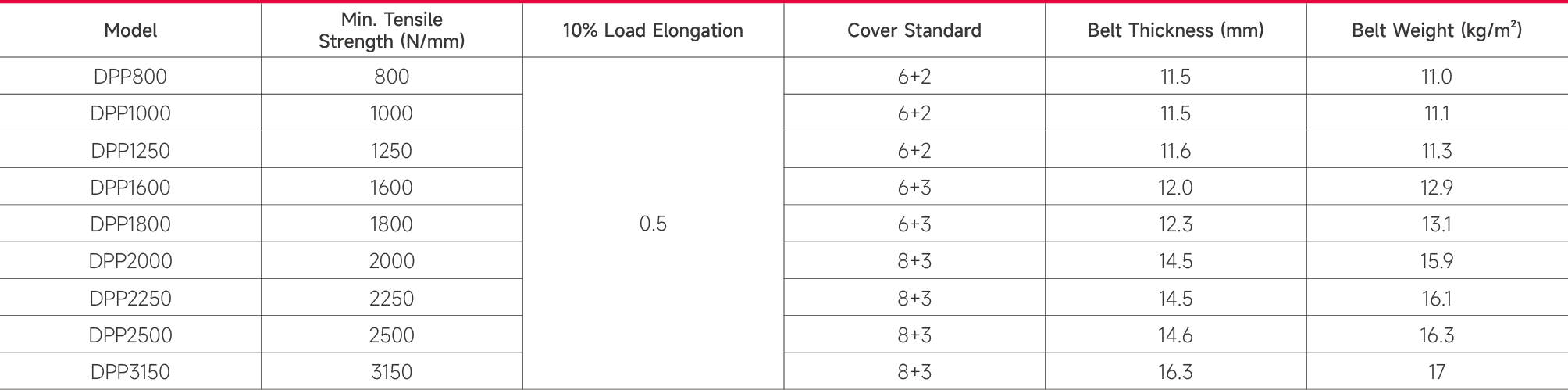

QMH has several types of Aramid Conveyor Belts available, depending on the specific needs of the application.

1. Woven Aramid Conveyor Belts: These belts are made by weaving aramid fibers into a fabric that is then embedded in elastomeric material. They offer excellent tensile strength and durability.

2. Laminated Aramid Conveyor Belts: These belts are made by laminating layers of aramid fabric and elastomeric material together. They are often used in applications where the belt needs to be both strong and flexible.

QMH offers customization options for Aramid Conveyor Belts, allowing customers to specify the belt's width, length, thickness, and other features to meet their specific needs. Additionally, some belts may be equipped with special features such as cleats or sidewalls to improve their performance in specific applications.

To ensure the long-term performance of an Aramid Conveyor Belt, it is important to perform regular maintenance and inspections. This includes checking for signs of wear and tear, ensuring that the belt is properly tensioned, and cleaning the belt as needed to remove debris and other contaminants.

In conclusion, Aramid Conveyor Belts are a high-performance option for conveying materials in various industries. Their combination of high tensile strength, heat resistance, durability, and cut and abrasion resistance makes them an excellent choice for applications where traditional conveyor belts may not be sufficient.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.