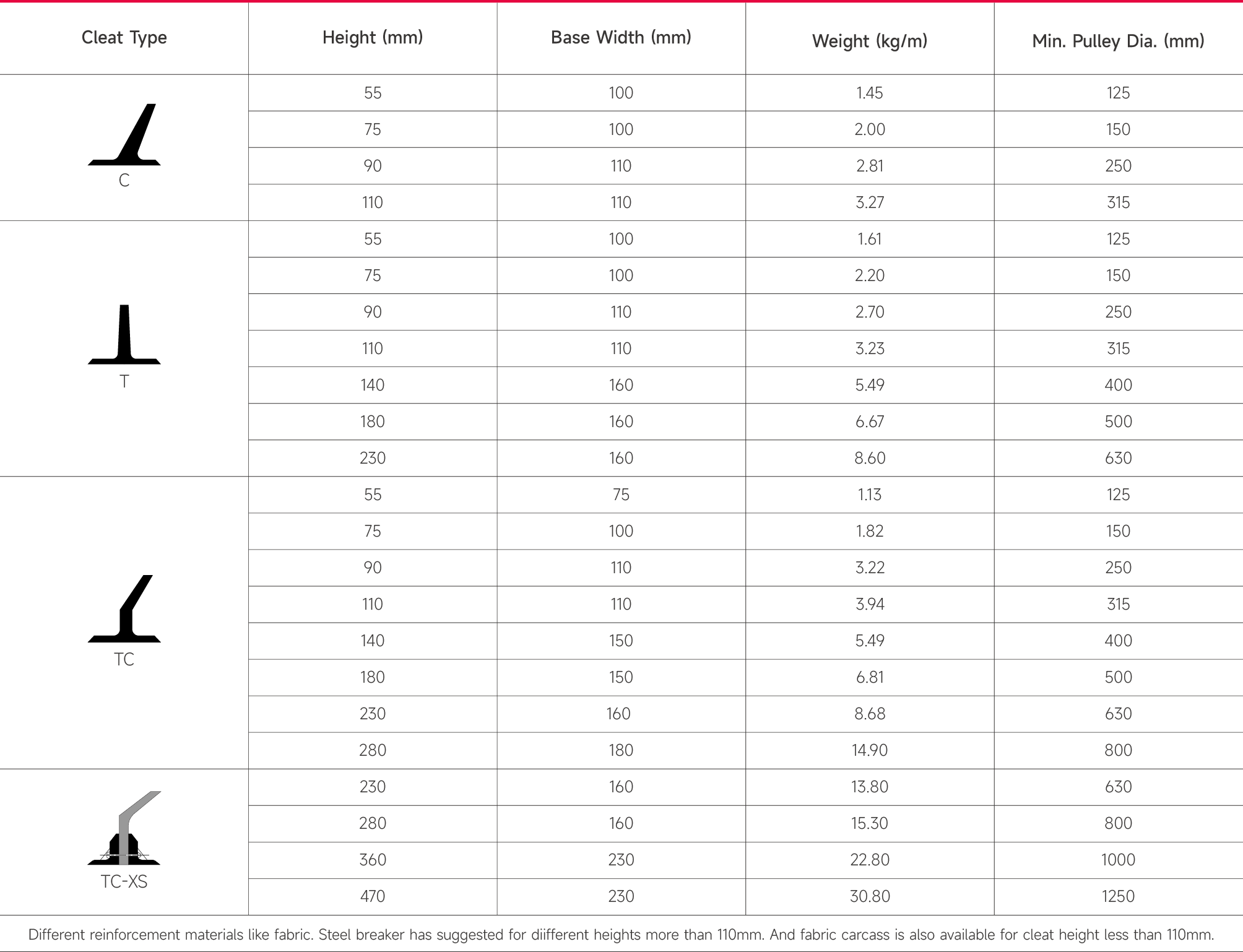

QMH sidewall conveyor belt cleats, take the full range of European standard molds and process. QMH use special rubber compound for cleats to enable excellent abrasion resistance and long service life. QMH offers four types of cleats: C, T, TC, and TC-XS(TCS), with heights available from 55mm to 600mm. TCS is special designed for heavy duty belt combined with stainless steel ladder bolt,steel cord breaker layer and EP fabric reinforcement .Type C normally for Pulley diameter in 125mm-315mm, Type T for pulley in 125mm-630mm, Type TC for pulley in 125mm-800mm, and Type TC-XS(TCS) for pulley in 630mm-1250mm. Different reinforcement materials like fabric, steel breaker has suggested for different heights more than 100mm, and fabric carcass is also available for cleat height less than 110mm.

Send InquiryQMH cleats are all installed by hot vulcanization technology to ensure the adhesion and stability of the cleat and base belts, and to extend the service life of the sidewall belts.

·European standard processes and molds.

·Special rubber compound to enable excellent abrasion resistance and long service life.

·High stiffness for excellent impact resistance.

·Small deformation under pressure.

·Optimized design to accommodate more materials in vertical lifting operation.

The sidewall conveyor belt mainly consists of a base belt, sidewall, and cleats. The sidewall, which are designed in a corrugated shape to easily pass around rollers, prevent materials from sliding or spilling. The cleats, arranged in a stepped manner, are available in T, TC, and TCS types, among which the TC type is most commonly used. These partitions serve to support materials and facilitate large-angle conveying, with angles ranging from 0 to 90 degrees.

The sidewall and cleats are made using special molds and are produced through secondary vulcanization, with the basic components being natural rubber from Malaysia and other countries. The base belt is composed of an top cover rubber, a bottom cover rubber, a belt core, and a lateral rigid layer. The belt core material withstands tensile forces and can be made of cotton canvas, nylon canvas, polyester canvas, or steel cord. The sidewall conveyor belt with cleats is made of high-strength materials such as metal, plastic, or rubber, exhibiting excellent wear resistance, corrosion resistance, and high-temperature resistance.

Industrial Equipment: In industrial settings, such as conveyors, mixers, and grinders, the sidewall conveyor belt with cleats prevents materials from spilling during transportation or processing, ensuring smooth production processes. It is also used to effectively isolate different substances in chemical,coal, sand,sludge, food, and pharmaceutical production processes, preventing cross-contamination and ensuring product quality.

Environmental Protection: In waste processing, it is used for waste classification and collection, reducing environmental pollution caused by waste. It is also applied in wastewater treatment and exhaust emission control, enhancing the operational efficiency of environmental protection facilities.

Benefits

Increased Efficiency: By preventing material or liquid spills, it reduces cleanup and maintenance time during production, thereby improving production efficiency.

Work Safety: With its wear resistance, corrosion resistance, and high-temperature resistance, it maintains stable performance in harsh working environments, ensuring staff safety.

Extended Equipment Lifespan: It effectively reduces equipment wear and corrosion caused by material spills, thereby extending equipment lifespan.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.