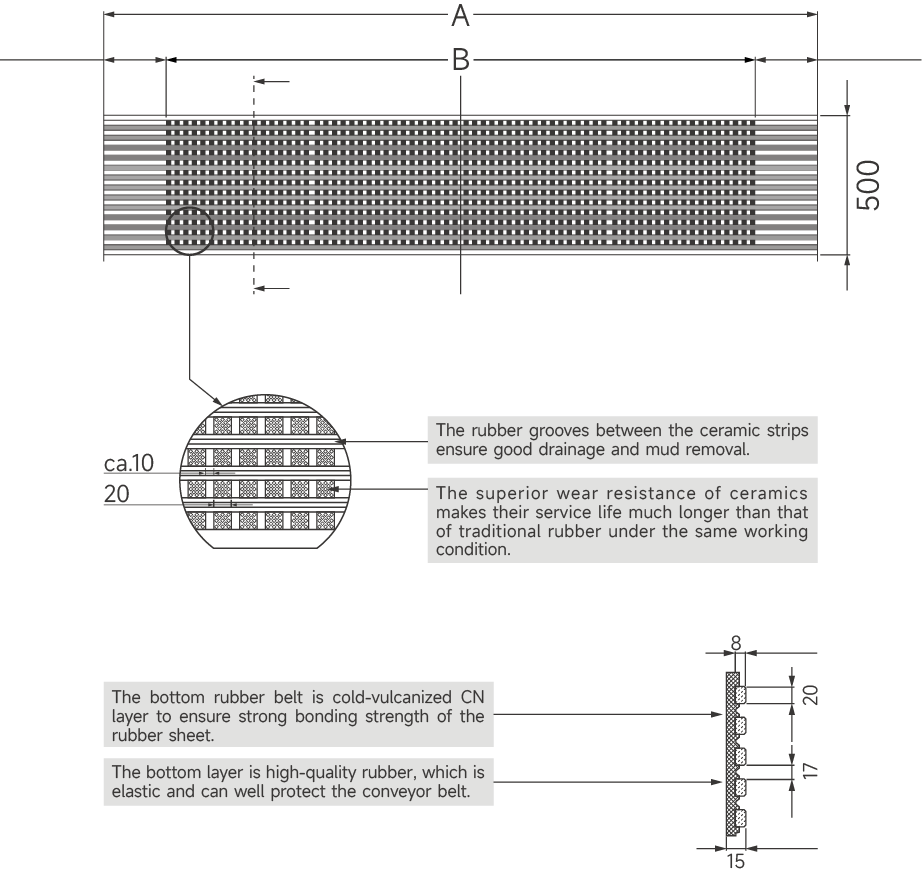

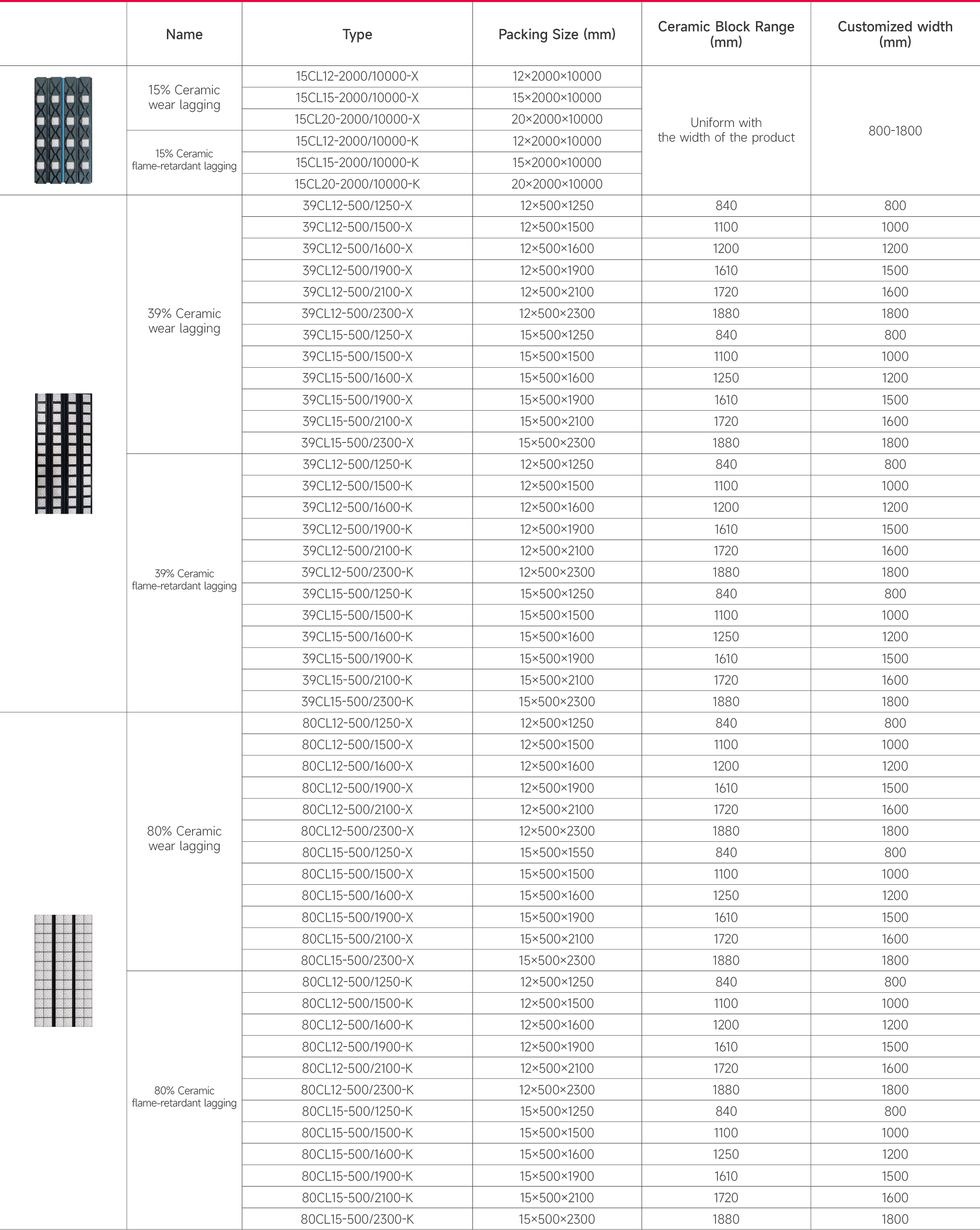

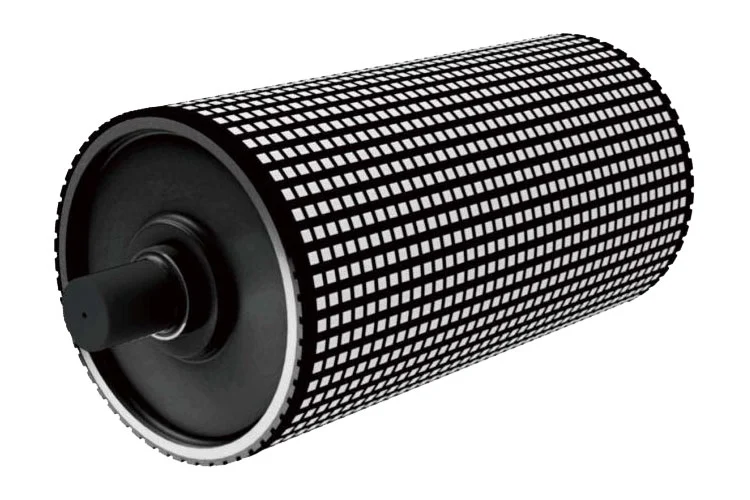

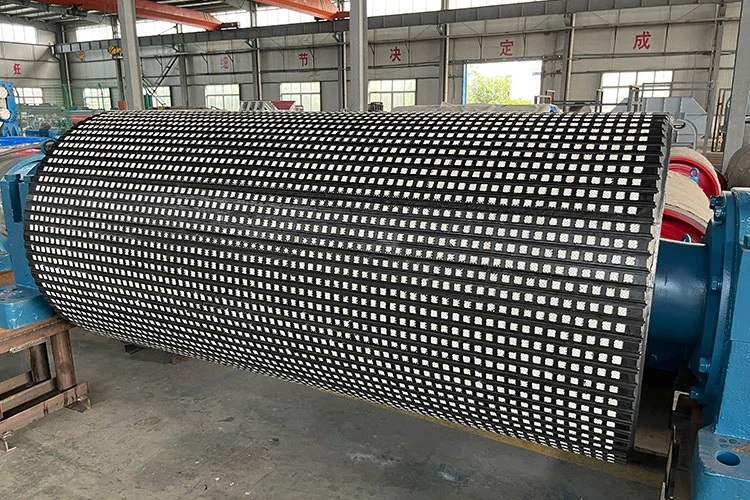

QMH ceramic pulley lagging is a way of pulley coating. The surface of the ceramic blocks is granular, suitable for driving pulleys. The ceramic blocks are embedded in rubber, along with a special rubber structure, which increases the friction coefficient between the blocks and the belt, preventing belt slippage. The rubber grooves between the ceramic blocks ensure maximum drainage and mud expulsion. The bottom layer uses high-quality rubber, which can effectively protect the conveyor belt and reduce the friction between the belt and the drive pulley. The ultra-strong wear resistance allows its lifespan to be 8-10 times that of traditional rubber under the same working conditions. Application range: Suitable for fabric belts and medium-low strength steel cord belts for driving wheel lagging.

Send Inquiry

The surface of each ceramic rubber plate is cast into the durable rubber plate by hundreds of independent small pieces of ceramic sheet, each ceramic sheet has the characteristics of the bulge, under the general conveyor belt pressure, thousands of unique casting convex points can produce positive traction, prevent slipping, extend the service life of the conveyor belt roller. At the same time, the elasticity of the underlying rubber can play a good impact resistance. Each ceramic rubber plate has a groove spaced at a certain distance, which can discharge foreign matter (dust, soil) on the pulley along the groove, so that the pulley has a unique self-cleaning function, especially suitable for wet working environment.

Alumina ceramic(Al2O3) is usually used. Alumina ceramic has extremely high hardness, second only to diamond, with a Mohs hardness of about 9. It has excellent wear resistance and can withstand long-term friction and impact of materials. In the conveying equipment of industries such as mining and coal, when materials containing hard particles such as ores and coal are transported on the conveyor belt, they will cause strong wear on the pulley. Ceramic materials can effectively resist this kind of wear. The shape and size of ceramic particles also have multiple choices. Generally, there are spherical, cylindrical, etc., and the particle size varies from a few millimeters to more than ten millimeters. Combinations of ceramic particles of different shapes and sizes can provide different friction properties to adapt to different material conveying requirements.

1. 92% aluminum oxide ceramic tiles embedded in rubber can prevent belt slipping.

2. Rubber grooves between ceramic tiles can ensure good drainage and mud removal.

3. Super wear resistance and long service life.

4. The bottom layer is made of high-quality rubber to reduce the friction and wear between the conveyor belt and the driving pulley.

5. Under the same load, the belt tension can be reduced and the belt life can be extended.

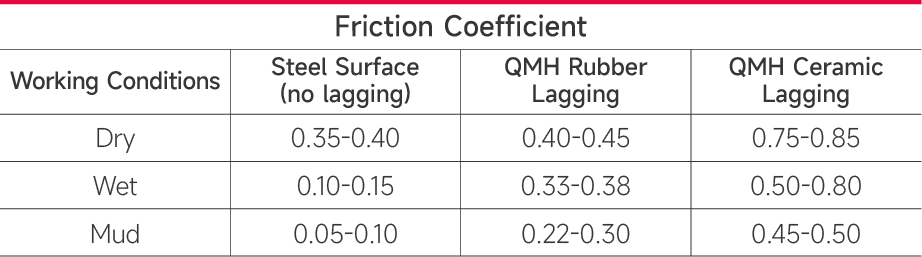

1. The high wear resistance of the surface ceramics, the use of the belt machine to drive the pulley, the special structure of the ceramics and special arrangement, as well as the special rubber structure, so that the friction coefficient between QMH ceramic pulley lagging and the belt increases, to prevent the belt from slipping.

2. Under the same load QMH ceramic pulley lagging reduce the tension of the belt, extend the life of the belt.

3. The wear resistance of the ceramic, so that the service life is more than ten times that of the original pulleys.

4. Suitable for high wear, easy to slip and material or surrounding environment moisture and other extremely harsh conditions

1. Pulley lagging for harsh working conditions.

2. Transport of various muddy, wet and highly abrasive materials.

3. High strength, high tension conveying systems.

4. Ceramic lagging with particles on the surface are suitable for driving pulleys.

Mining industry: For pulleys in ore mining and transportation equipment, such as drive pulleys for underground conveyor belts and conveyor pulleys in ground ore processing workshops. Ores have high hardness and large particles, which cause great wear and impact on pulleys. QMH Ceramic pulley lagging can handle these problems very well.

Port and terminal industry: Widely used in bulk cargo loading, unloading and transportation equipment at ports. Whether it is the transportation of bulk cargo such as coal, ore or grain, QMH ceramic pulley lagging can improve the operating efficiency and reliability of equipment, reduce equipment maintenance time, and adapt to the busy operation rhythm of ports.

Power industry: In the coal conveying system of thermal power plants, QMH ceramic pulley lagging can ensure the stability of coal transportation, reduce pulley wear and maintenance costs, and improve the operating efficiency of power generation equipment.

Building materials industry: In the transportation process of building materials such as cement and sand, QMH ceramic pulley lagging can prevent the wear and corrosion of building materials on pulleys and ensure the efficient and stable transportation of building materials.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.