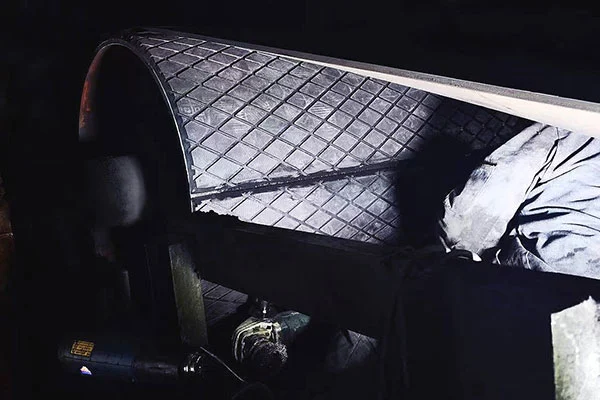

QMH diamond pulley lagging refers to the pulley lagging that does not need to be carved on the surface, which is a diamond pattern formed in one piece during production. Preformed patterns, suitable for drive pulley rubber coating, effectively prevent material accumulation on the surface of the pulley, protect the pulley from wear and corrosion, enhance the friction between the pulley and the belt, prevent the belt from slipping and deviating. Diamond pattern grooves facilitate drainage and sewage discharge. QMH diamond pulley lagging is suitable for high-strength, high-tension conveyor systems, as well as roller rubber coating in extremely harsh environments.

Send InquiryDiamond pulley lagging is suitable for fabric belt and high strength cable belt drive pulley covering, it is carved on the basis of wear-resistant pulley lagging diamond pattern, has higher friction than flat pulley lagging, can make the friction between the drive pulley and the belt increase, power output efficiency is higher and more stable.

1. The diamond-shaped groove is conducive to drainage and sewage discharge.

2. Effectively avoid material accumulation on the Pulley surface and prevent the belt from running off track.

3. QMH diamond pulley lagging can greatly enhance the friction of the pulley lagging, can maximize the protection of the metal surface of the pulley does not adhere to the material and deviation, increase the sliding friction coefficient, reduce the slip between the pulley and the conveyor belt.

4. Protect the Pulley and prevent the Pulley surface from wear and corrosion.

1. Preformed pattern, suitable for drive pulley lagging.

2. Suitable for long-distance, large-diameter pulley lagging.

3. Suitable for high-strength fabric belt, steel cord belt conveyor system pulley lagging.

When the operator does not need to disassemble the pulley, it can easily realize the coating of the diamond pulley lagging on the driving pulley, which greatly reduces the adhesive strength of the worker and saves the downtime of the conveyor belt. QMH diamond pulley lagging can meet the special requirements of power plants, iron and steel plants, coking plants, cement plants, granaries, mines, docks, subways and other industries, extend the life of the conveying system, reduce the cost of the conveying system. Installation environment requirements:

1. Temperature and humidity:

The temperature and humidity of the installation environment have a significant impact on the curing effect of glue and the performance of rubber sheets. Generally speaking, the ideal temperature range is 15 - 30°C. Too low temperature will lead to a slower curing speed of glue and may even fail to cure completely, affecting the bonding strength between the rubber sheet and the roller; too high temperature may cause the glue to dry too quickly and not have enough time to fully soak the surfaces of the rubber sheet and the roller, which will also reduce the bonding effect. The humidity should be kept at a relatively low level. Generally, it is recommended that the humidity not exceed 70%. A high humidity environment easily causes the glue to absorb moisture and reduces its bonding performance. Moreover, it may cause the surface of the rubber sheet to get damp and affect its service life.

2. Cleanliness:

The installation site should be kept clean to avoid dust and impurities from contaminating the glue and rubber sheet. If dust particles are mixed into the glue or adhere to the surface of the roller and rubber sheet, an isolation layer will be formed between the rubber sheet and the roller, reducing the bonding force and causing the rubber sheet to easily fall off during use. Before installation, it is best to clean the installation site and cover the installation area with materials such as plastic sheeting to prevent dust from entering.

3. Ventilation conditions:

Good ventilation conditions help to discharge the harmful gases generated during the volatilization and curing process of glue. Especially for some glues containing organic solvents, volatile organic compounds (VOCs) will be released during the application and curing process. Poor ventilation will not only endanger the health of operators but also may affect the drying and curing speed of glue. If installed in an enclosed space, effective ventilation equipment such as exhaust fans should be provided.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.