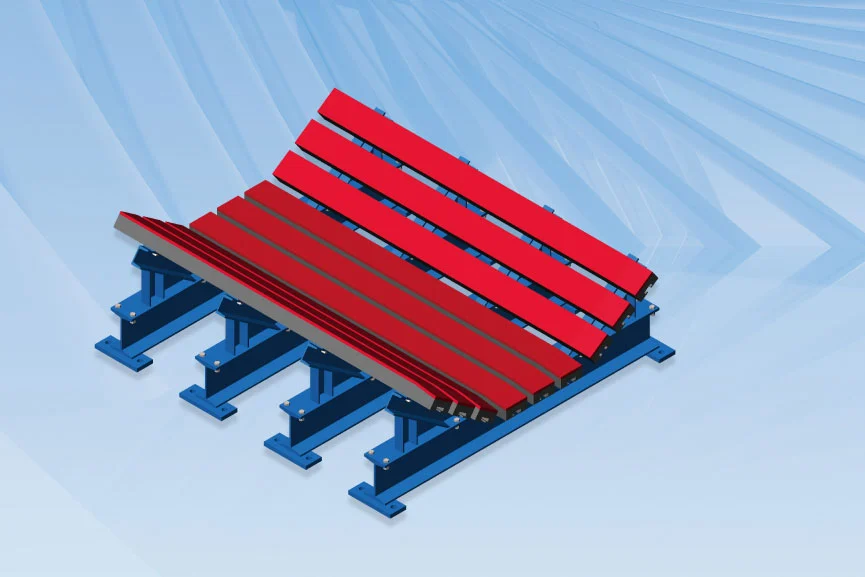

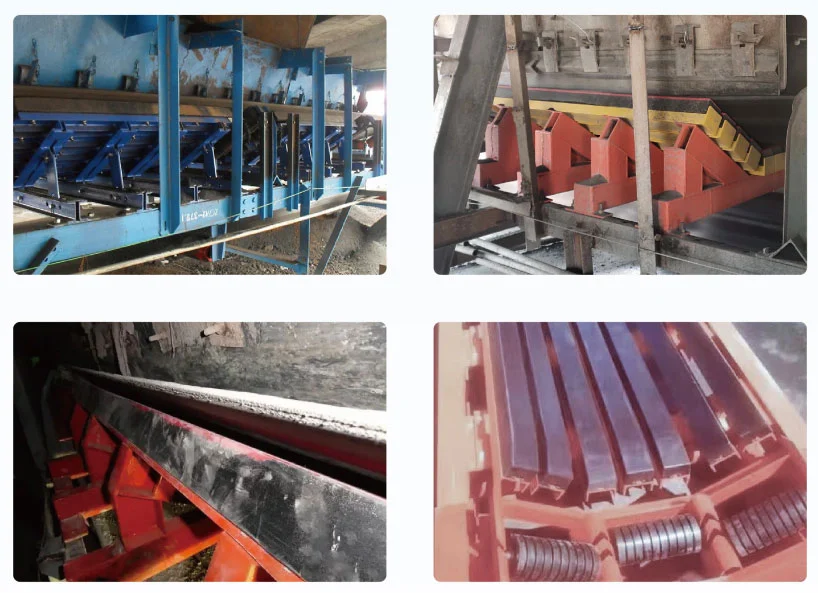

About the role of an impact bed in conveyor systems is crucial for ensuring efficient material handling. QMH impact beds regular protect conveyor belts, absorb shock loads, support full belt width, and ensure material stability during loading. An impact bed is designed to absorb the energy from falling materials at transfer points, thereby protecting the conveyor belt from damage. This not only extends the life of the belt but also minimizes downtime and maintenance costs. Impact beds are essential in maintaining the integrity of the conveyed materials and preventing spillage. By providing a stable and cushioned support, an impact bed enhances the overall efficiency and reliability of the conveyor system, making it a vital component in industries dealing with heavy and abrasive materials.

Send InquiryQMH impact beds regular are designed to help protect the belt at key transfer point areas and keep conveyed material where it belongs – on the belt. Impact beds are available in seven different configurations to help fit your application requirements.

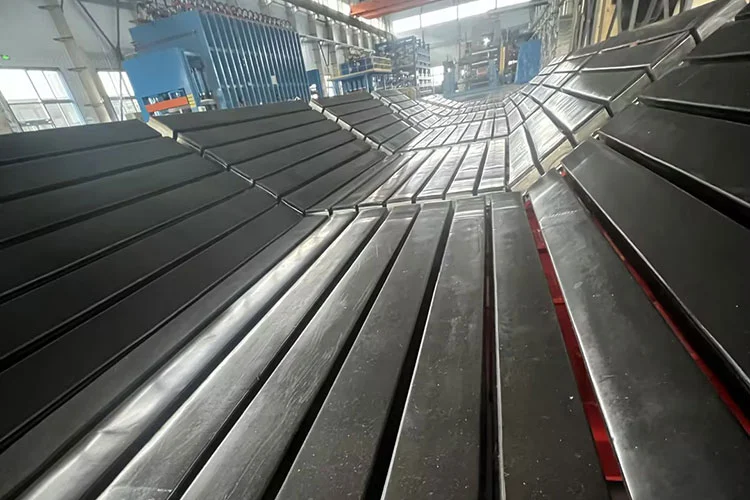

Standard Impact Bed: Comprises a series of impact bars mounted on a frame.

Provides general protection for conveyor belts in standard loading zones.

Commonly used in a variety of industries such as mining, aggregate, and material handling.

Engineered or custom designs are also available helping to ensure that QMH will have the correct solution for your application.

QMH Manufacturing impact beds regular are engineered and designed to protect the conveyor belt at all key transfer points. These impact beds are built to absorb shock loads while supporting the full width of the conveyor belt and help keep conveyed material in place; on the belt where it belongs. Designed to reduce cost and maintenance, impact beds will eliminate bent idler shafts and frames at the critical transfer point. This also means no more worn-out rollers to replace.

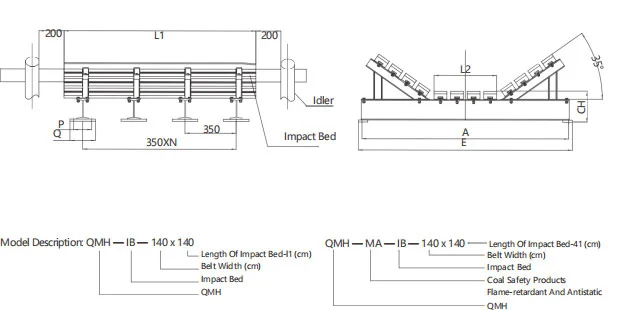

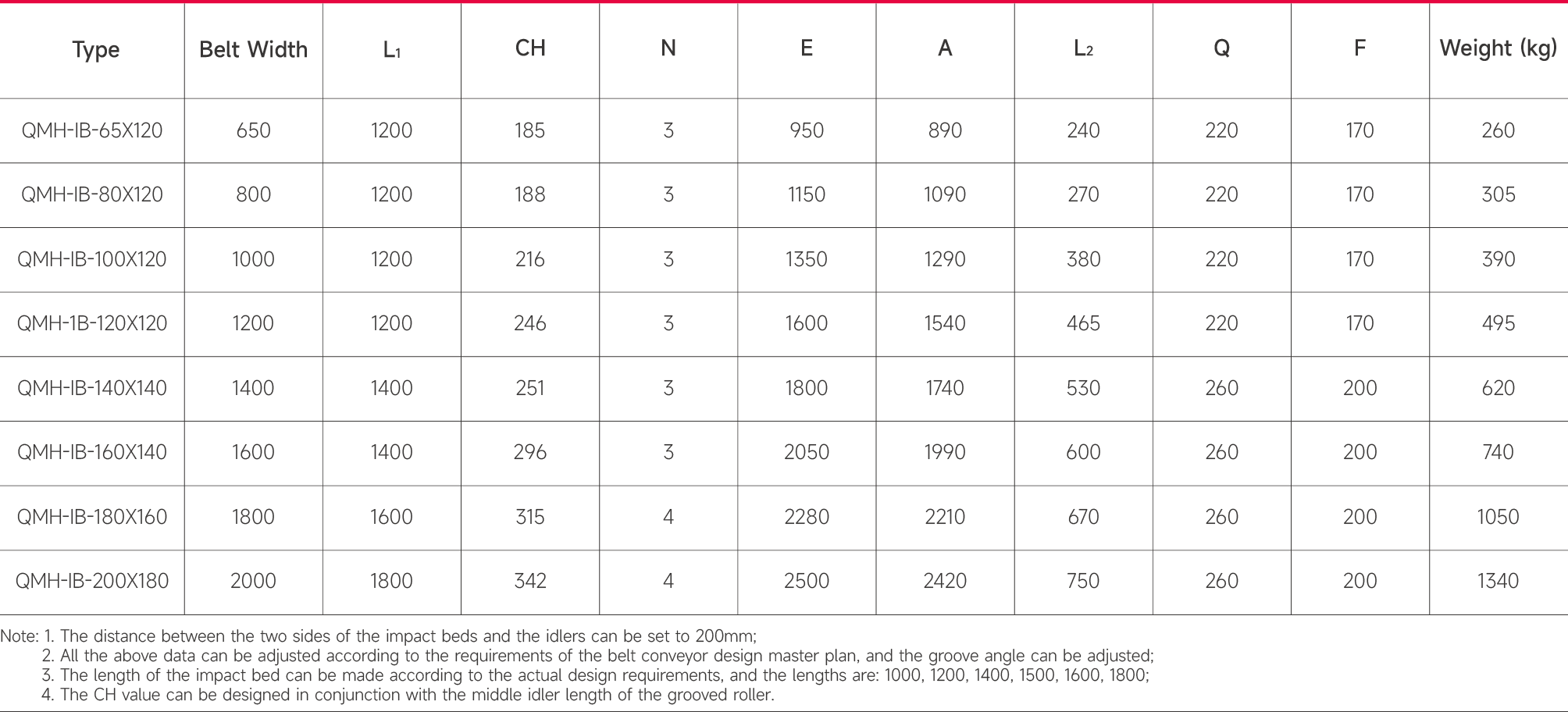

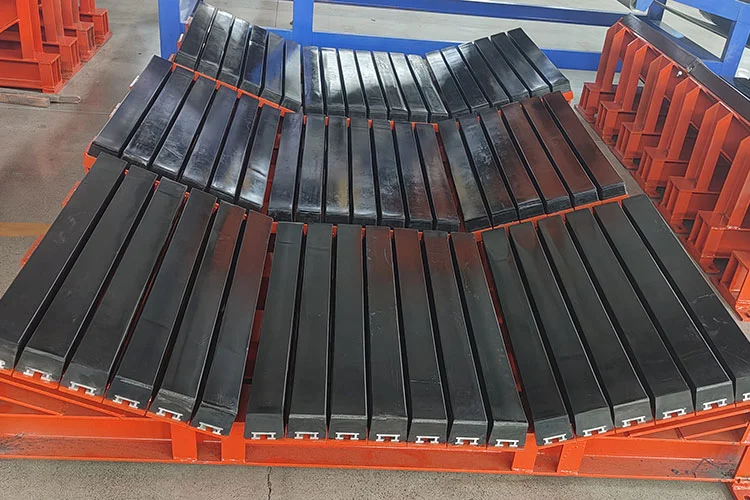

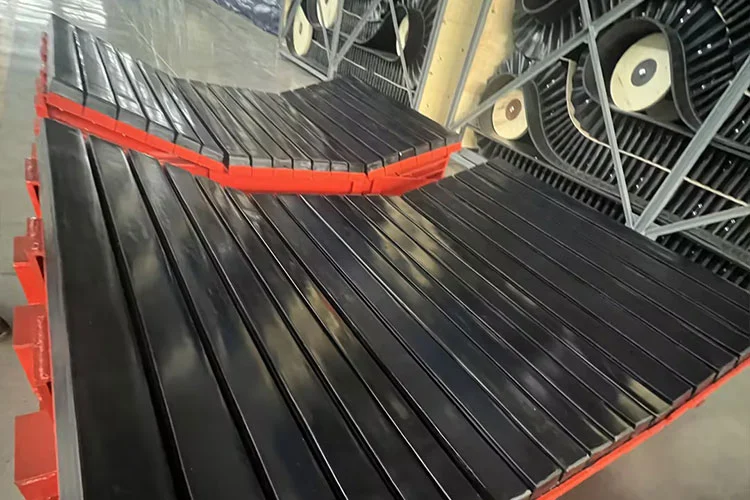

New concept of impact bed fully adjustable from 0 to 45 degrees angle or progressive angle from 20 to 35 degrees. This is the solution for these conveyors presenting a too short distance between tail pulley and loading point.

Impact bars of 4′ or 5′, made of rubber and UHMW for friction reduction, are easily replacable without removing the skirting over the belt, simply by sliding them out.

This impact bed present the best value on the market. It is available for belt from 18″ to 72″.

QMH Impact beds play several crucial roles in conveyor systems, especially in industries where heavy materials are transported. Here are the primary roles of impact beds:

1. Protecting the Conveyor Belt

Impact beds absorb the shock and impact of materials being loaded onto the conveyor belt, preventing damage and extending the belt's lifespan.

By cushioning the impact, they help prevent tears, punctures, and other types of physical damage to the belt.

2. Reducing Material Spillage

Impact beds provide a stable surface that helps to seal the load zone, reducing the chances of material spillage along the conveyor belt.

They support the belt in the load zone, preventing it from sagging and causing spillage.

3. Improving Conveyor System Efficiency

By providing uniform support, impact beds help in maintaining the proper alignment of the conveyor belt, reducing downtime and maintenance.

With fewer interruptions and less spillage, the material flows more smoothly, improving overall system efficiency.

4. Reducing Maintenance Costs

By protecting the belt and structure from impact damage, impact beds reduce the wear and tear on the conveyor system.

Reduced maintenance needs and fewer belt repairs lead to less downtime, which translates to cost savings.

5. Enhancing Safety

A stable belt reduces the risk of accidents caused by belt misalignment or material spillage.

By minimizing maintenance and repairs, there is less need for workers to be in potentially hazardous areas, enhancing overall workplace safety.

6. Supporting Heavy Loads

Heavy-duty impact beds are designed to handle large and heavy materials, providing the necessary support to prevent damage to the belt and conveyor structure.

They help distribute the weight of heavy loads more evenly across the belt, reducing stress on any single point.

7. Adapting to Various Conditions

Different types of impact beds can be tailored to various applications, including extreme temperatures, corrosive environments, and heavy-duty usage.

They can be adjusted or customized to fit specific conveyor belt widths, load capacities, and trough angles.

New concept of conveyor impact bed featuring a fully adjustable sturdy frame to fit different idlers angles providing a perfect fit for all type of belt conveyors.

The versatility and effectiveness of impact bed combination systems make them suitable for a wide range of industries. Here are some applications and benefits in various sectors:

Mining Industry: In the mining industry, conveyor belts are subjected to heavy and abrasive materials such as ore and coal. QMH impact bed combinations provide the necessary protection and support to handle these materials efficiently. The impact bed component absorbs the shock from falling ore, preventing damage to the belt, while the slider ensures smooth and consistent movement. This results in reduced maintenance costs and increased operational efficiency, allowing mining operations to maximize productivity.

Aggregate Industry: The aggregate industry involves the transportation of materials like sand, gravel, and crushed stone, which can cause significant wear on conveyor belts. QMH impact bed combinations help to mitigate this wear by providing robust protection and support. The impact bed cushions the impact of heavy loads, while the slider maintains belt alignment and reduces friction. This leads to longer belt life, fewer maintenance requirements, and improved efficiency in aggregate processing operations.

Power Generation: In power generation, particularly in coal-fired power plants, conveyor systems are essential for transporting coal to the boilers. QMH impact bed combinations enhance the reliability and efficiency of these conveyor systems by protecting the belt from the impact of heavy coal loads and ensuring smooth material flow. This results in reduced downtime, lower maintenance costs, and a more efficient coal handling process, contributing to the overall performance of the power plant.

Cement Industry: The cement industry deals with abrasive materials like clinker and limestone, which can cause severe damage to conveyor belts. QMH impact bed combinations provide the necessary protection to handle these materials effectively. The impact bed absorbs the shock from falling clinker, preventing belt damage, while the slider ensures consistent support and reduces wear. This leads to longer belt life, reduced maintenance costs, and improved efficiency in cement production operations.

Recycling Industry: In the recycling industry, conveyor belts handle a variety of materials, including metals, plastics, and glass. QMH impact bed combinations offer the versatility and durability needed to manage these diverse materials. The impact bed cushions the impact of heavy and sharp objects, protecting the belt from damage, while the slider ensures smooth and consistent movement. This results in fewer maintenance requirements, reduced downtime, and increased efficiency in recycling operations.

Food Processing Industry: In the food processing industry, maintaining the integrity of conveyor belts is crucial to ensure product quality and safety. QMH impact bed combinations provide the necessary protection to handle heavy and bulky food products. The impact bed cushions the impact of falling products, preventing belt damage, while the slider ensures smooth and consistent movement. This contributes to a more efficient and reliable production process, ensuring that food products are transported safely and efficiently.

Ports and Terminals: Ports and terminals rely on conveyor systems to handle bulk materials such as grain, coal, and minerals. QMH impact bed combinations enhance the reliability and efficiency of these conveyor systems by protecting the belt from the impact of heavy loads and ensuring smooth material flow. This results in reduced maintenance costs, increased operational efficiency, and improved productivity in bulk material handling operations.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.