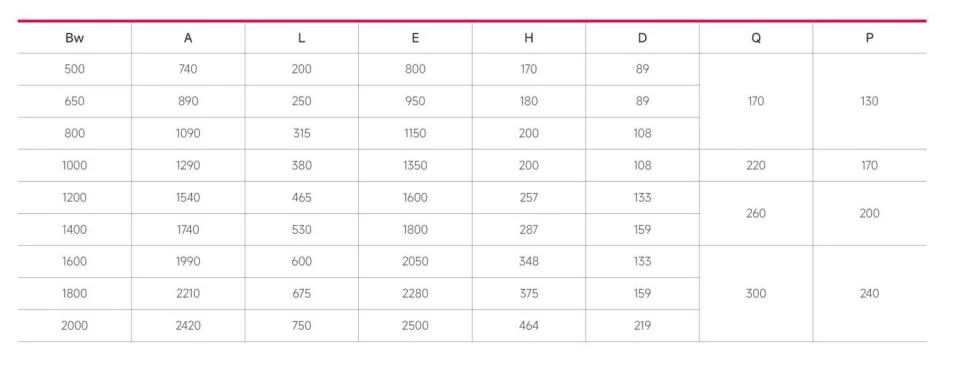

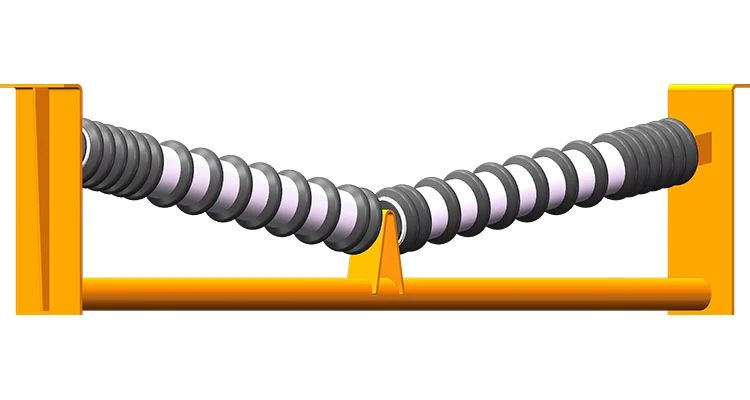

QMH New easy-to-detach impact idler is an important component for belt conveyors, usually designed with 3 idlers and installed on the bearing side of the conveyor belt. The QMH idlers group under the guide chute is tightly installed and affected by the guide chute above, which causes a lot of manpower and time in maintenance and replacement. QMH new easy-to-detach idlers group is easy to get replaced, which can be completed very fast.

Send Inquiry

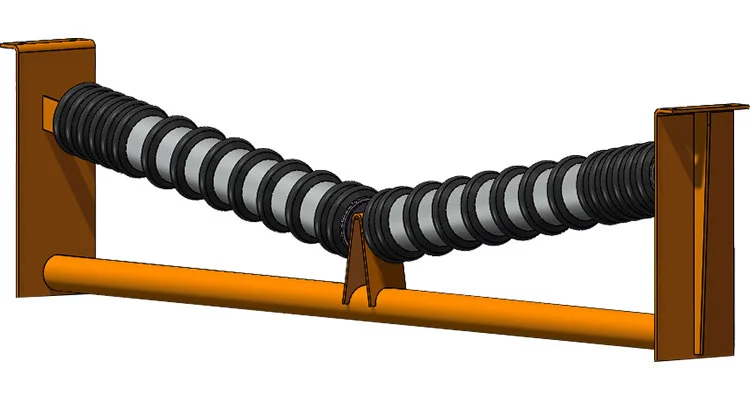

It includes a groove-type support buffer structure composed of at least two groups of side idlers units. The upper edge generatrix of the idler surface of each group of side idler units is an inclined structure with the outer side higher and the inner side lower. The side idler unit includes a buffer side idler, a side support and a middle support. The idler end of the buffer side idler is provided with a transition block at the lower end to form an articulated match with the groove on the middle support. The idler end at the high end is provided with a transition plate that can be detachably fixed to the inner side of the side support.

Quick replacement method: Remove the matching structure of the transition plate and the side support, and the idler end of one side of the buffer side idler will be separated from the side support and can swing down along the inner side of the side support, so that the upper edge generatrix of the idler surface will gradually separate from the lower belt surface of the conveyor belt to produce an operating gap, and then lift the transition block at the lower end and separate the groove to complete the removal of the buffer side idler, and the installation operation can be reversed. For the middle idler unit, by controlling the extraction of the detachable pad at the bottom end of the middle support, the buffer middle idler and the middle support are lowered as a whole, so that the idler surface is separated from the conveyor belt surface, and the quick replacement of the buffer middle idler is completed.

It abandons the defects of the traditional rigid idler system that is difficult to disassemble and inefficient, and can ensure online convenient and fast replacement, disassembly and maintenance, reduce the labor burden of maintenance personnel, and significantly improve the maintenance and replacement efficiency of idlers.

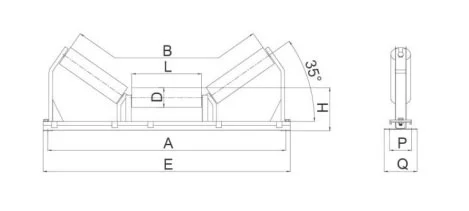

The following are some common detailed technical parameters of new easy-to-remove buffer idlers:

Diameter: According to the Chinese national conveyor industry standards, the common standard types of buffer idler diameters for belt conveyors with a bandwidth of 500mm-1400mm are φ89mm, φ108mm, φ133mm, and φ159mm. With the emergence of wide-bandwidth belt conveyors, the diameter of buffer idlers has also tended to increase. For example, in conveyors in some large mines or ports, larger diameter buffer idlers, such as φ219mm, may be used.

Length: The length of buffer idlers for conveyors with different bandwidths is also different. Common ones are: conveyors with a bandwidth of 500mm, the length of buffer idlers is about 190mm; conveyors with a bandwidth of 650mm, the length is about 240mm; conveyors with a bandwidth of 800mm, the length is about 305mm; conveyors with a bandwidth of 1000mm, the length is about 375mm; conveyors with a bandwidth of 1200mm, the length is about 455mm; conveyors with a bandwidth of 1400mm, the length is about 525mm.

Drag coefficient: Generally required to be no more than 0. 022, excellent new and easy-to-remove buffer idlers are easy to remove. The force coefficient can be ≤0. 018, which can effectively reduce the energy consumption of the conveyor.

Radial runout: The radial runout is usually specified to be ≤0. 7mm, and the products with better quality can be controlled at ≤0. 5mm to ensure the smooth operation of the idler and reduce the wear on the conveyor belt.

Rotational resistance: The rotational resistance is generally required to be ≤1N, and the better products can reach ≤1. 9N. Smaller rotational resistance helps to improve the operating efficiency of the conveyor.

Axial load: The axial load capacity must meet ≥20000N to ensure that the idler will not be axially displaced or damaged when subjected to material impact and conveyor belt tension.

Axial displacement: The axial displacement should be controlled between 0. 5-0. 7mm, and the high-quality products can be ≤0. 25-0. 3mm to prevent the idler from moving during operation and affecting the normal operation of the conveyor belt.

1. Material and environmental adaptability parameters

idler material: mostly polymer materials are used, which are light in weight and have a specific gravity of about one-seventh of steel. The weight of the idler is about half of that of ordinary idlers, with small rotational inertia and small friction with the belt. At the same time, it has good wear resistance, self-lubricating performance, anti-static performance, corrosion resistance and flame retardant performance, etc., and can adapt to the harsh working environment of mining, coal, cement, electricity, metallurgy, building materials, chemical industry and other industries.

Bearing: Generally, large clearance deep groove ball double sealed bearings are selected, which can make the idler have ideal static balance and dynamic balance. Its operating temperature range is wide, usually -40℃-90℃.

2. Sealing performance parameters

Sealing method: Most of them adopt labyrinth sealing structure, which can effectively prevent impurities, water and air from affecting the idler. Corrosion inside the idler extends the service life of the bearing.

3. Parameters related to the quick-change function

Side idler disassembly clearance: For the side idler unit with quick-change function, after the matching structure of the transition plate and the side support is disassembled, the idler end on one side of the buffer side idler is separated from the side support and can swing down along the inner side of the side support, so that the upper edge generatrix of the idler surface is gradually separated from the lower belt surface of the conveyor belt. The operating clearance is generally required to facilitate the lifting and groove separation operations of the transition block.

Middle idler disassembly height: In the middle idler unit, by controlling the extraction of the removable pad at the bottom end of the middle support, the buffer middle idler and the middle support are lowered as a whole, so that the idler surface is separated from the conveyor belt surface. The generally required lowering height can ensure that the old buffer middle idler can be perfectly separated from the embedded groove on the middle support from bottom to top to complete the quick replacement.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.