QMH Nylon idlers are low friction coefficient, abrasion resistance, not easy to damage the belt. With excellent self-lubrication, in the process of use, without oil injection and can operate in harsh environmental conditions, not easy to jam, with good anti-magnetic characteristics. QMH Nylon Polymer Idlers are resistant to corrosion of weak acid, weak alkali and organic solvent, non-toxic and non-polluting can withstand repeated shocks and vibrations. QMH Nylon idler itself has light weight, only one third of the metal parts, easy to install, with low maintenance rate, low noise, smooth operation, energy saving, which can improve the service cycle nylon idler dust, used in a multi-ash environment, not easy to let water in.Nylon Polymer Idlers are installed below the receiving section of the conveyor.

Send Inquiry1. Light weight and small rotational inertia: The polymer material used for QMH Nylon Polymer Idler is light in weight, with a specific gravity of one-seventh that of steel. The weight of the Idler made of it is about one-half of that of ordinary Idlers, with small rotational inertia and small friction between the Idler and the belt. Easy installation, no maintenance;

2. High toughness: The toughness itself is more than 10 times that of ordinary metals.

3. Long life: Low voice (3-7DB) smooth operation. The life span is 3-5 times that of metal Idler.

4. Corrosion-resistant and flame-retardant: The Idler body and seals are made of polymer materials, which are anti-smoldering, anti-aging, anti-chemical (acid, alkali and organic solvent) corrosion and flame-retardant. Nylon Idler use environment temperature range: -40℃ ~ 80℃; They are suitable for corrosive environments such as coal washing plants, coking plants, and chemical plants.

5. Anti-static: It can reduce the risk of accidents caused by static sparks and improve safety in use.

6. Self-lubricating: The polymer material used for the Idler body has good self-lubricating properties and does not damage the belt.

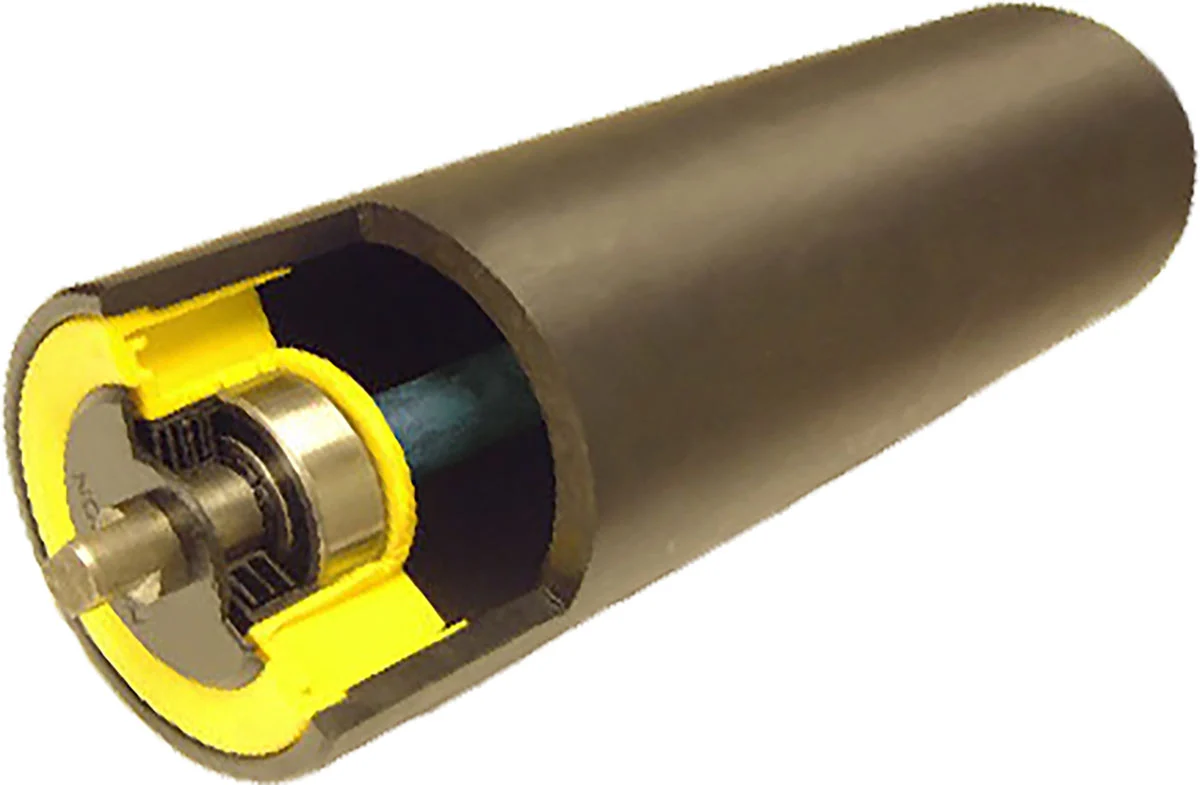

1. Idler body: usually made of polymer materials, some may also be metal materials coated with wear-resistant rubber and other buffer materials, with good wear resistance and impact resistance.

2. Bearings: generally use large clearance deep groove ball double sealed bearings of domestic and foreign brands, so that the Idler has ideal static balance and dynamic balance, and the rotation resistance is better than the national standard, which can effectively reduce the running resistance.

3. Seals: specially designed with the characteristics of foreign and domestic labyrinth seals, effectively preventing impurities, water, and air from eroding the inside of the Idler.

Widely used in belt conveyor systems in mining, coal, cement, electricity, metallurgy, building materials, chemical industry and other industries.

1. Standards: According to China's national conveyor industry standards, there are 4 standard types of buffer Idler diameters for belt conveyors with a bandwidth of 500mm-1400mm, namely: φ89mm, φ108mm, φ133mm, and φ159mm. With the emergence of wide-bandwidth belt conveyors, the diameter of QMH Nylon Polymer Idlers has also tended to increase.

2. Installation precautions:

① Increase the density of installation;

② Check frequently and replace damaged Idlers in time.

For conveyor belts with large drop heights, it is recommended to install a buffer air lock and replace the impact Idlers with a impact bed.

3. Purchase precautions: Attention should be paid to indicators such as the radial runout of the Idler, the flexibility of the Idler, the axial movement, the dustproof performance of the Idler, the waterproof performance, the axial load-bearing performance of the Idler, and the impact resistance of the Idler.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.