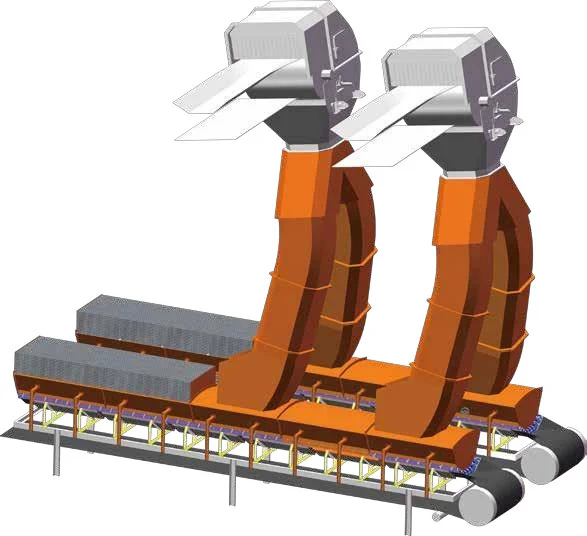

The first consideration in dust control should always be the minimization of the amount of dust created.Consequently, it is best to design conveyor systems with minimal material drop distances. The size and cost of the transfer point enclosure and the other components of a conveyor's dust management system are directly related to the volume of air that must be pulled thought the system. The air movement through the transfer point allows QMH Engineers to design Dust Suppression System for controlling the release of fugitive dust particles. A slight negative pressure is wanted inside the enclosure. This condition allows for air to be pulled into the enclosure so that fines and airborne dust are retained in the structure, rather than carried out. This requires a large dust collection system because the airflow created by the movement of material through the transfer point generates positive pressure through the system. The collection system exhaust air volume must be equal to or greater than the rate of air movement. QMH Airflow Dust Suppression System is a unified system combining Dust-scrape, Air-scrape, Trail-scrape, and Containment Seal provides an integrated solution for improving overall dust containment.

Send InquiryDustScrape:

Primary dust suppression: At the heart of effective dust management is QMH DustScrape, designed to capture dust at critical transfer points. QMH DustScrape utilizes a filter cloth that captures fine dust particles produced within bulk material transfers, allowing air permeability to accommodate over-pressure. Dust-scrape protects workers and enhances operational efficiency by suppressing dust where it forms. QMH Dust Scrape can be easily retrofitted to most existing conveyor belt systems. It is available in different filter cloth sizes (2, 4, 6 m²) for all conveyor belt widths.

QMH DustScrape is easy to install, durable, maintenance-free and contact free, and can also be combined with existing dust collection systems. The combination of filter cloth and AirScrape, the patented sidewall seal (not included), makes the "DustScrape"a highly effective system against dust generation and thus helps to improving occupational safety and environmental protection. A highly efficient compact solution for operation dust-free conveyor belts at comparatively low cost and without the energy input of dust.

Air-scrape:

Complementing Dust-scrape is Airscrape, an innovative contact-less skirting system. AirScrape uses airflow generated by the moving belt to create a suction effect that keeps fine dust within the load zone. This method minimizes the risk of dust escaping into the atmosphere and reduces belt wear, which is crucial for high-volume operations. The selection of which size AirScrape to use, depends on load width, existing chute wall width and trough angle. AirScrape requires belt overhang outside the chute at the transfer point. Because AirScrape is not touching the belt surface, due to the diagonal array of lamellas, it creates a Venturous effect. Airflow created by the material fl ow can escape through the filter cloth, dust particles will remain inside the Dustbox and drops back into the material flow. AirScrape's design ensures that dust containment is maintained without additional maintenance burdens. Its ability to capture fine dust without contact extends equipment life and reduces operational disruptions, making it an ideal solution for dusty environments.

Tail Scrape:

Even with primary containment systems, dust and material spillage can still occur, which is why TailScrape offers secondary protection. Located at the tail of conveyors, TailScrape directs spillage and fine particles back onto the belt, preventing leakage and ensuring that dust remains contained.

This additional containment layer is essential in reducing dust exposure, where minimal leakage can pose significant health risks. TailScrape also improves dust management and minimizes material loss, optimizing operational efficiency. The filter cloth retains dust particles, generated by the falling process of the material in the conveying stream and at the same time is air-permeable for the resulting overpressure. The special antistatic filter cloth is designed for dust particles. The special self-cleaningproperty of the antistatic fi lter cloth enables dust to be retained for a very long time. DustScrape is also effective against drift and can be supplied in different filter cloth qualities, depending on the environment, also in stainless steel

Q-Containment Seal: The final component of this unified system is the Containment Seal, which manages internal pressure at transfer points. Engineered with low-friction polyurethane, the seal ensures that bulk materials and dust remain contained while preventing dust from escaping under pressure. This is crucial where heavy material flows can easily disrupt containment efforts. The Q-Containment Seal's durability also reduces wear on both the conveyor and the sealing system, extending the life of the equipment and lowering maintenance costs over time.

By integrating DustScrape, AirScrape, TailScrape, and Q-Containment Seal, QMH has manufactured a robust, unified dust control system that improves operational efficiency. This integrated approach improves safety and delivers long-term cost savings by reducing maintenance and extending equipment life. For quarry and the bulk material handling industry, a unified dust management system is essential for securing a safer, more efficient future.

AirScrape® is a highly effective contact-free conveyor skirting and sealing system that acts as a side seal, suspended over the conveyor belt. With its unique diagonal arrangement of hardened lamellae, air is led from the outside into the middle of the belt, creating powerful air suction. The material movement together with the moving belt support increases the suction effect enabling fine dust particles to remain in the conveyor section. Additionally, coarse materials pushing outward are led back to the middle of the belt by the lamellae which can significantly minimize spillage. The AirScrape® innovative and patented design delivers a tri-fold positive effect that includes material spillage and dust formation reduction particularly at critical transfer points. Additionally, due to the skirting and sealing system's ability to hover freely above the conveyor belt, skirt friction and belt damage can be eliminated, service life of other conveyor components can also be extended. Dimensions AirScrape® is available in pairs of left and right hand side 2 metre inter-connectable pieces to form any required length and is available for belt overhangs (G) of 55 - 143 mm in the sizes Large, Medium and Small. Installation AirScrape® is installed using spacers, floating the blades 0 - 1 mm freely above the belt and is attached to the outside of the chute by lifting tensioners via a simple screw system. It is longitudinally and laterally adjustable to follow the contours of conveyor belt rollers and the belt trough angle.

Dust suppression at the source, reaches ultra-low emission standards. Dust concentration can be reduced to ≤8mg/m3.

Dust can be controlled without bag dust collector: Reducing the load of existing bag dust collectors, which efficiently improve dust control without bag dust collectors.

Saving floor space: The equipment does not require additional floor space, is easy and quick installation, and can be reconstructed on site.

No belt abrasion: The skirt rubber has no contact and damage with the belt, which can extend the service life of the belt.

Reduce operating costs: Low energy consumption and low frequency of spare parts replacement.

Reduce maintenance costs: Reduce cleaning labor costs and bag dust collector maintenance costs, low maintenance frequency.

More energy-saving: Low operating energy consumption when combined with a bag dust collector, The wind flow is reduced by more than 60%, reducing electricity costs by less fan consumption.

QMH Dust Suppression System is very useful for all bulk material handling system specifically Cement Plant, Coal Power Plants, Mining , Harbor and Terminal for loading and unloading of coal, lime stone and material with fine particles.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.