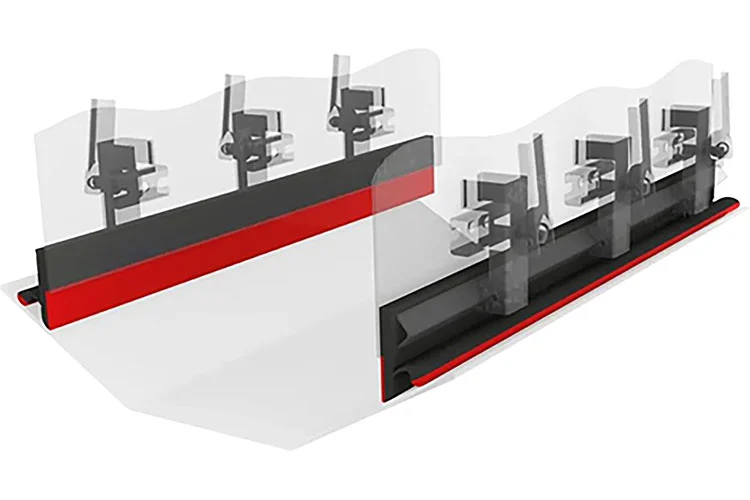

Rubber Skirting in conveyor belt systems refers to the sealing material that runs along the edge of the conveyor belt. Its primary purpose is to create a tight seal between the belt and the Skirt Rubber to prevent material spillage and control dust emissions. This is particularly crucial in industries where bulk materials, such as grains, minerals, or aggregates, are transported. QMH skirt rubber helps maintain a clean work environment, reduces material waste, and enhances the overall efficiency and safety of the conveyor system.

Send InquiryA Skirt Rubber is an integral component of conveyor belt operations, especially in industries where bulk material handling is a routine operation. The basic concept of a Rubber skirting involves a sealing mechanism that runs along the edges of the conveyor belt. This seal prevents the spillage of materials being transported and controls dust emissions, which are two significant challenges in conveyor operations.

The roles of skirting in enhancing conveyor efficiency and safety are multifaceted:

Spillage Prevention: By forming a tight seal along the conveyor belt's edge, QMH skirt rubber prevent materials from falling off the belt, thereby reducing material loss and the need for cleanup operations.

Dust Control: QMH Skirt Rubber helps to minimize airborne dust generated by the movement of materials, contributing to a healthier work environment and reducing the risk of respiratory issues among workers.

Extended Belt Life: By preventing material spillage and buildup on the conveyor components, QMH skirt rubber reduce the wear and tear on the belt, thereby extending its operational life.

Improved Safety: Reduced spillage and dust contribute to safer working conditions, minimizing the risk of slip-and-fall accidents and visibility issues.

Enhanced Operational Efficiency: By minimizing disruptions caused by spillage and dust, our Skirt Rubber ensure smoother, more continuous operations, leading to higher productivity.

Cost Savings: Reducing material loss, cleanup time, and maintenance needs translates into significant cost savings for businesses.

Compliance with Environmental Regulations: Effective dust control measures, such as those provided by skirt rubber help businesses comply with environmental regulations regarding dust emissions.

Customization and Flexibility: QMH Skirt rubber can be tailored to fit various conveyor designs and operational needs, making them a versatile solution for different industry requirements.

The efficiency and longevity of a Skirt Rubber hinge on several key components, each playing a pivotal role in its overall functionality. Base on the functionality right selection of skirting is crucial for optimizing the performance and durability of the conveyor system. QMH is leading manufacturer of flowing type of skirt rubber.

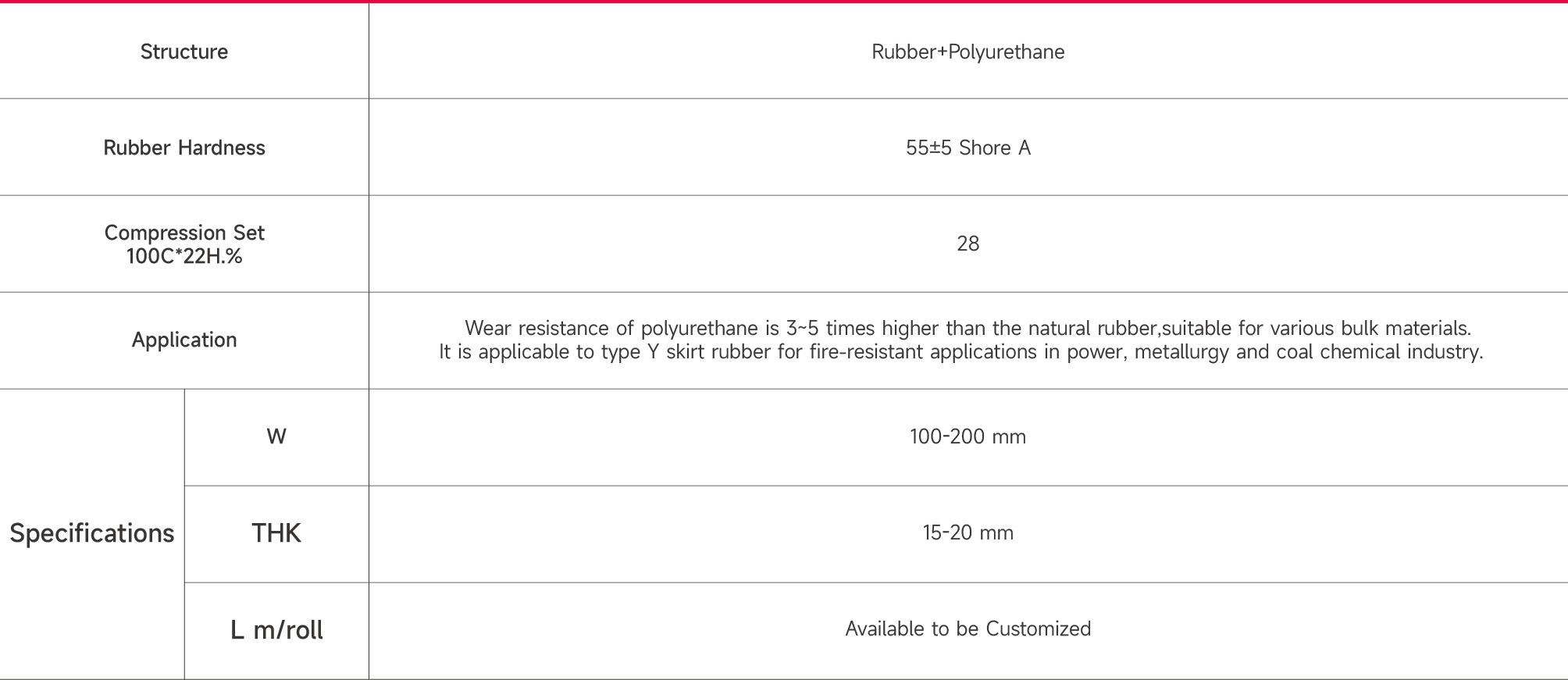

YX-type Skirt Rubber

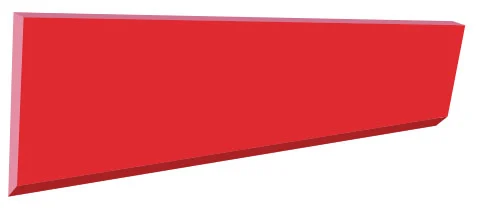

The Y-shaped design improves the sealing of the conveyor's guide chute and reduces the spillage and fume dust. The abrasion resistance of polyurethane is 3-5 times that of natural rubber. Special accessories can make installation more simple and quicker, suitable for various bulk materials.

Y-Type Skirt Rubbe

The Y-shaped design improves the sealing of the conveyor guide chute and reduces the spillage and fume dust Special installation accessories are available for purchase, which are easy and quick to install and suitable for powdery bulk materials.

Skirt Board Design

The design of the skirt board plays a critical role in the effectiveness of the skirt Rubber. An optimal belt conveyor skirt board design ensures that the skirting rubber maintains a consistent, effective seal against the conveyor belt, regardless of variations in belt speed, load, and environmental conditions. The design considerations include the height, thickness, and angle of the skirt board, which must be tailored to the specific requirements of the conveyor system to achieve maximum sealing efficiency and minimize wear on both the skirt and the belt.

High Abrasion-resistant skirt rubber

Polyurethane skirt rubber is extremely resistant to wear, tear and impact, and has a service life 3-5 times longer than pure rubber skirts. Ideal for mining, aggregates, foundries and all light industries.

Beyond the primary components, various conveyor belt accessories play supportive roles in the functionality of a skirt rubber. Accessories like splice protectors are crucial for maintaining the integrity of the belt's seams, preventing material and dust from infiltrating the belt layers, which could lead to premature wear and failure. These accessories, while seemingly minor, contribute significantly to the overall performance and longevity of the conveyor system, ensuring that it operates smoothly and efficiently.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.