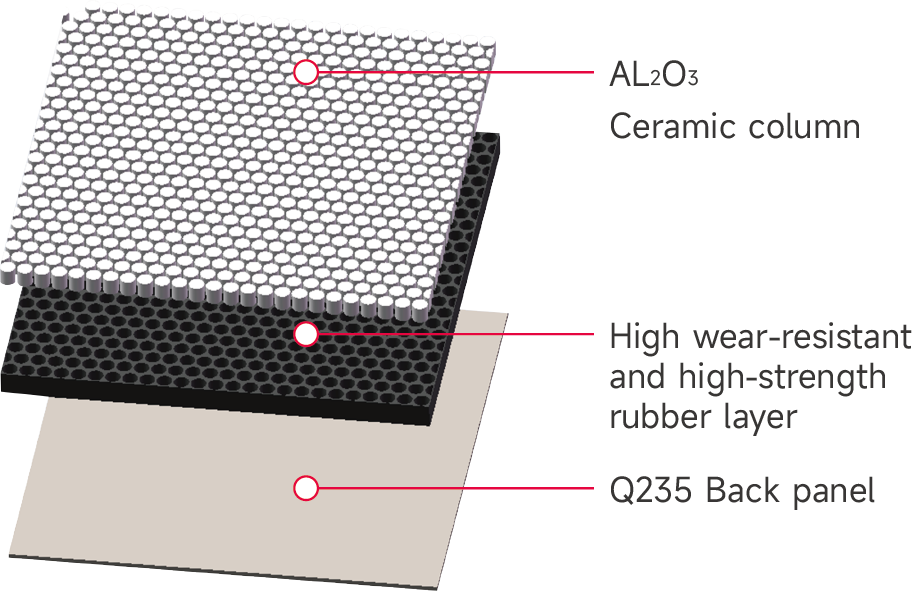

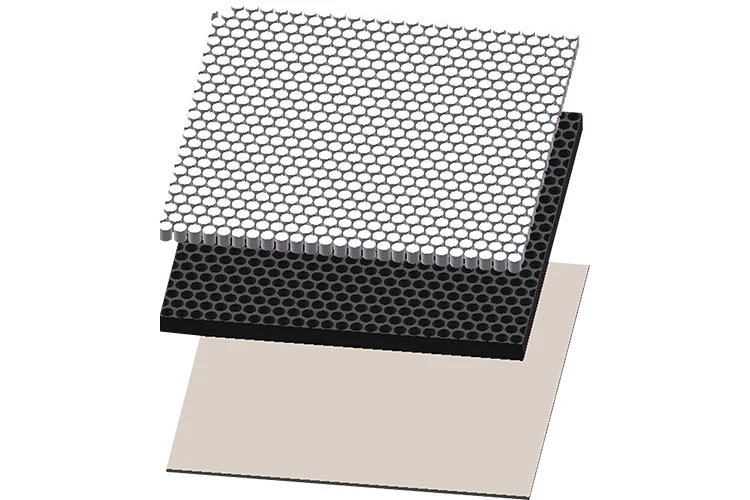

QMH pure ceramic wear lining is a protective plate made of ceramic as the main raw material for resisting material wear. Its main components are ceramic materials such as alumina (Al₂O₃). Alumina ceramics have the characteristics of high hardness and good wear resistance. Usually, its alumina content can reach more than 90%. Some high-performance pure ceramic wear-resistant linings can even have an alumina content of 95% - 99%.

Send Inquiry

1. Super wear-resistant:

The hardness of ceramics reaches HRA88 or above, and it has strong impact resistance. The hardness of QMH pure ceramic wear-resistant lining is very high, and the Mohs hardness is generally between 8 and 9, second only to diamond (Mohs hardness is 10). This high hardness enables it to effectively resist the friction and impact of various hard materials. For example, during the crushing and transportation of ore, even if materials with higher hardness such as iron ore and quartz stone come into contact with it, it is difficult to cause scratches or wear to it. Under the same grinding media and working conditions, metal wear-resistant materials may show obvious wear within 1000 hours, while pure ceramic wear-resistant liners can be used for more than 3000-5000 hours before the same degree of wear occurs.

2. High temperature resistance:

It can be allowed to operate at 0℃-500℃ for a long time (conventional feeding systems can meet this requirement)

3. Corrosion resistance:

Due to the chemical stability of the ceramic material itself, it can be used in some acidic or alkaline environments. For example, on the inner wall of some reactors in the chemical industry, or inside the tailings conveying pipeline of the mine, when encountering liquids or gases containing acidic or alkaline components, the pure ceramic wear-resistant liner can maintain the stability of its structure and performance, and will not be corroded as easily as metal materials.

4. Compressive strength:

QMH pure ceramic wear liner has a high compressive strength, which can generally reach 2000-3000MPa. This means that it can withstand greater pressure and will not easily break when subjected to the accumulation pressure and impact pressure of materials. For example, in the chute of a coal mine, when a large amount of coal accumulates and slides, it can stably withstand these pressures.

5. Anti-falling:

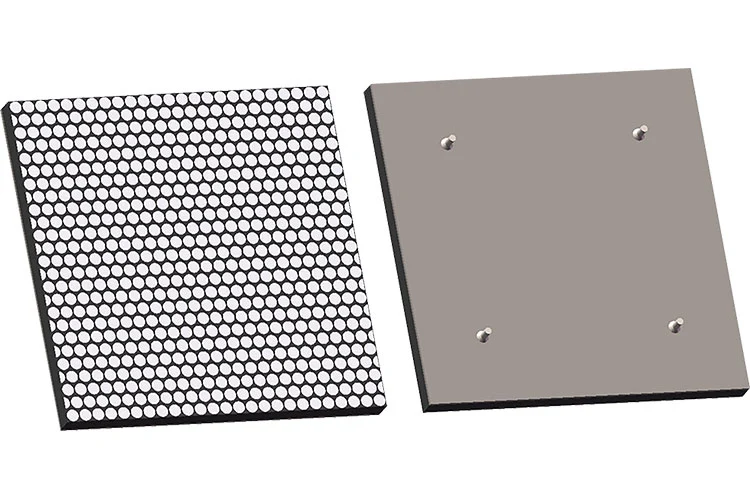

Each ceramic has a high-strength and high-wear-resistant bolt passing through the ceramic and welded to the bottom steel plate, combined with strong glue bonding, double insurance to ensure that it does not fall off.

6. Professional welding:

Adopt professional stud welding process.

7. Support customization:

The shape, size and thickness of the ceramic block or liner can be customized on demand.

Installing pure ceramic wear-resistant linings in the crushing equipment, ball mill, chute, conveyor belt and other parts of the mine can effectively reduce the wear of ore on the equipment and extend the service life of the equipment. For example, in the ore crushing workshop, after QMH pure ceramic wear lining is installed on the inner wall of the crushing chamber of the crusher, the wear of the ore on the inner wall of the equipment during the crushing process is greatly reduced, and the maintenance cycle of the equipment can be extended by 1-2 times.

1. Power industry:

In the coal transportation system of thermal power stations, QMH pure ceramic wear linings are used in locations such as coal hoppers, coal drop pipes, scraper conveyors, etc., which can resist the friction and impact of coal blocks. Especially in the coal drop pipe with a large drop of coal, pure ceramic wear-resistant lining can reduce the wear of coal blocks on the pipe wall and reduce the risk of pipeline leakage and blockage.

2. Iron and steel industry:

In the process of iron and steel making, such as the chute, ladle, ladle and other parts of the blast furnace, QMH pure ceramic wear lining can prevent the erosion and wear of high-temperature molten iron, molten steel and slag on the equipment. For example, after installing QMH pure ceramic wear lining on the chute of the blast furnace tapping port, the damage to the chute by the erosion of molten iron is significantly reduced, and the service life of the chute can be extended from the original several months to more than one year.

3. Cement industry:

In the raw material mill, clinker mill, cement storage and other equipment in cement production, QMH pure ceramic wear lining can resist the wear of cement raw materials and finished cement. In the cement mill, the lining can effectively reduce the wear of the grinding body and materials on the mill cylinder, and improve the grinding efficiency and service life of the mill.

QMH pure ceramic wear-resistant lining has various installation methods. Common ones are welding installation, adhesive installation and bolt connection installation.

Welding installation: It is necessary to pre-set metal mounting parts on the liner, and fix the liner to the metal surface of the equipment by welding the metal mounting parts. This method is firmly installed, but attention should be paid to the welding process to avoid thermal damage to the liner.

Adhesive installation: Use a special ceramic adhesive to stick the liner to the surface of the equipment. This method is simple to operate and will not have a thermal impact on the equipment, but it has high requirements on the performance of the adhesive, and it is necessary to ensure that the adhesive can maintain the bonding strength for a long time in the working environment.

Bolt connection installation: Drill holes on the liner and the surface of the equipment respectively, and then use bolts to fix the liner. This method is convenient for disassembly and replacement of the liner, but it is necessary to ensure the strength and sealing of the bolts to prevent material leakage from the bolt holes.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.