QMH pure ceramic wear lining is made of three materials: ceramic, rubber and steel plate. The toughened ceramic tile is vulcanized in the steel plate groove filled with special rubber using a hot vulcanization process: alumina ceramics can enhance the wear resistance of the equipment, rubber can act as a buffer material, and the rubber used has flame retardant, heat resistant, acid and alkali-resistant properties, and can adapt to a variety of material environments. QMH ceramic wear lining is widely used in thermal power, iron and steel, smelting, coal, mining, chemical, cement, port and other industries, suitable for conveying system, powder system, ash discharge, dust removal system and other wear large mechanical equipment, can reduce the impact of wear on equipment.

Send Inquiry

1. Super wear-resistant: Alumina corundum ceramics, with a hardness of HRA88 or above, have excellent wear resistance;

2. Impact resistance: The toughened ceramic formula ensures that the ceramics are not easy to break, and an unique spherical ceramic can be designed to resist the impact of large pieces of materials; the composite rubber layer further enhances the impact resistance of the lining;

3. Acid and alkali resistance: The main component of the ceramics is Al203, which has stable chemical properties and strong acid and alkali resistance;

4. Anti-falling: The ceramic, rubber and steel plate is vulcanized in one piece, and the hot vulcanization process makes it more firmly combined. Each piece of ceramic has a penetrating bolt passing through the bottom steel plate, which is firmly welded and has double insurance;

5. Easy to install and replace: A whole lining plate, and modular installation, make easy replacement and installation, which can be used only in certain heavy wear and strong impact areas, saving operating costs;

6. Reduce maintenance: Super wear resistance greatly reduces the frequency of maintenance, which can save costs and labor costs;

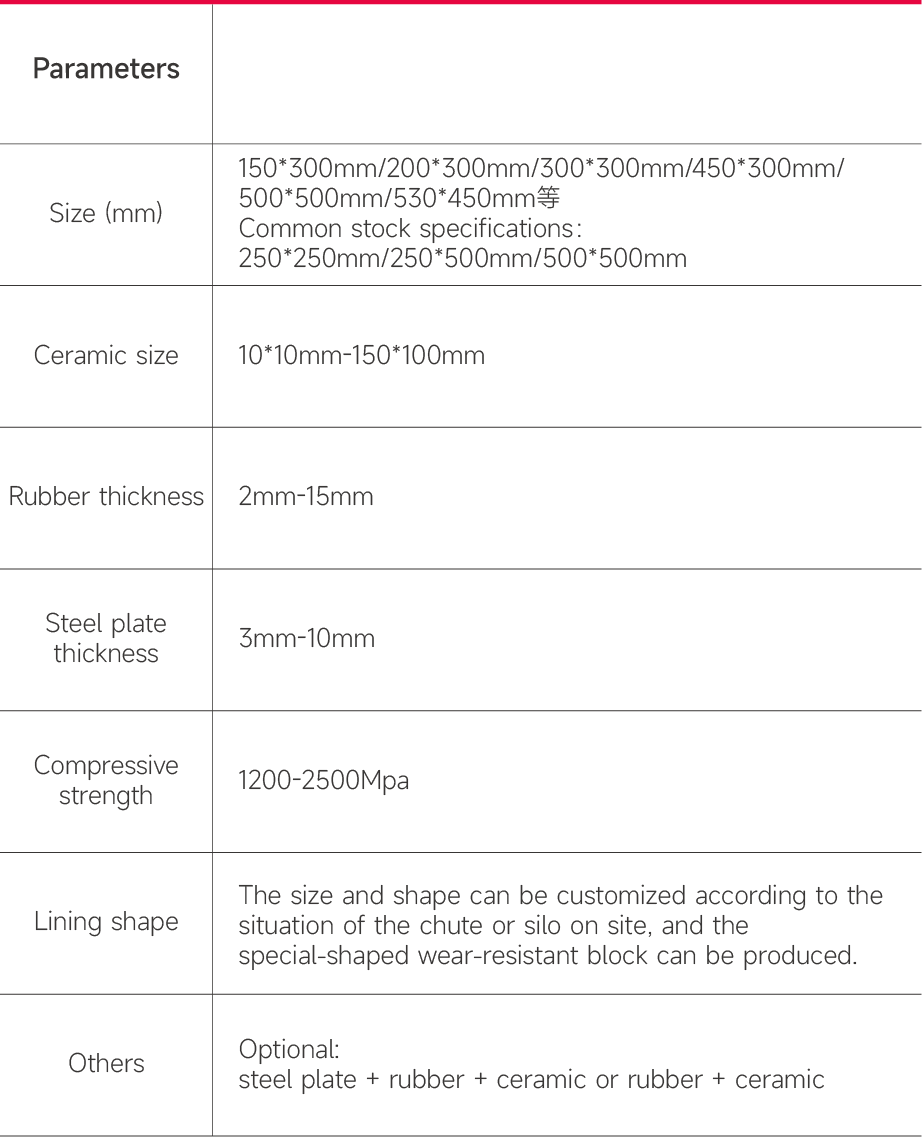

7. Support customization: The working temperature is-50°C-100°C, and the shape, size and thickness of the ceramic block or lining plate can be customized as needed.

QMH pure ceramic wearing lining is suitable for mechanical equipment with large wear such as feeding hopper of conveying system, powder making system, ash removal and dust removal system, etc. It can reduce the impact wear on the equipment. lt is widely used in thermal power, steel smelting, coal, mining chemical industry, cement, port and other industries to transport materials, and as anti-wear lining for silos, hoppers and other equipment in batching systems. Because of its unique physical and chemical properties, ceramic liner exhibits excellent wear resistance, impact resistance and corrosion resistance under high temperature, high pressure and corrosive environment.

Compared to traditional liner, QMH ceramic wear lining has a longer service life and significantly reduces maintenance costs, and the thermal expansion coefficient of the ceramic liner is small, which can effectively reduce the thermal stress and ensure the stable operation of the equipment. In many industrial fields, the application of QMH ceramic wear lining is increasingly widespread, and it has become an important choice to improve equipment performance and extend service life.

It is suitable for mechanical equipment with large wear such as feeding hopper of conveying system, powder making system, ash removal and dust removal system, etc, lt can reduce the impact wear on the equipment, it is widely used in thermal power, steel smelting, coal, mining, chemical industry, cement, port and other industries to transport materials, and as anti-wear lining for silos, hoppers and other equipment in batching systems.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.