QMH flame-retardant conveyor belt is a specialized type of industrial conveyor belt designed to resist ignition and limit the spread of fire, making it ideal for use in environments where flammability is a concern.

Send InquiryQMH flame-retardant conveyor belts are engineered to meet strict safety standards, ensuring that they can withstand exposure to high temperatures and potential ignition sources without compromising their structural integrity or causing the fire to spread. QMH flame-retardant belts are commonly used in industries such as coal mining, electricity generation, and chemical processing, where the risk of fire is relatively high.

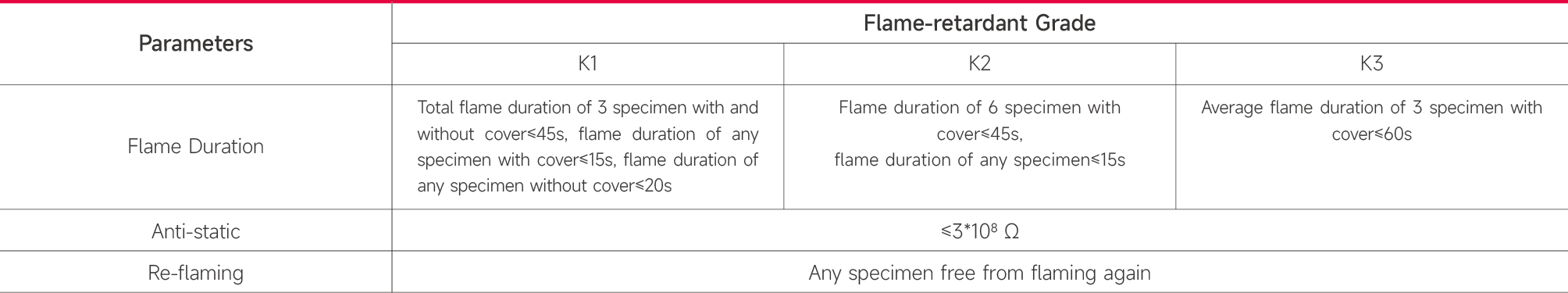

1. Flame Resistance:

QMH belts are treated with flame-retardant chemicals or materials that significantly slow down the rate of combustion. They often comply with international standards such as EN 14973, which specifies requirements for flame-resistant conveyor belts used underground.

2. Durability and Strength:

QMH flame-retardant conveyor belts are designed to be highly durable, withstanding the wear and tear associated with heavy-duty industrial applications. They typically have high tensile strength and are resistant to tearing, ensuring reliable performance even under extreme conditions.

3. Resistance to Other Elements:

In addition to flame resistance, QMH belts are also resistant to oil, acids, alkali, and other harsh chemicals. They are also designed to be waterproof and aging-resistant, maintaining their performance over time.

4. Environmental Adaptability:

QMH flame-retardant conveyor belts can operate stably in various harsh environments, including high temperatures, humidity, and dusty conditions. They are suitable for use in underground mines, power plants, and chemical plants where environmental conditions can be challenging.

QMH flame-retardant conveyor belts are widely used in industries that require high levels of safety and reliability.

Coal mining:where the risk of fire and explosion is high due to the presence of methane and other flammable gases.

Electricity generation:particularly in power plants that use coal, oil, or gas as fuel sources.

Chemical processing:where flammable and explosive materials are handled and stored.

1. Flame Retardant EP Conveyor Belt

Type:QMH EP Conveyor Belts with Flame Retardant Properties (e.g., EP100, EP125, EP200)

Material:Polyester or nylon fabric with rubber cover

Features:Heat-resistant and flame-retardant, suitable for high-temperature environments

Applications:Used in coal mines, cement plants, and other industrial applications where heat resistance is required. They are applicable to transport non-corrosive lumps, granular materials and powders in hazard environment.

2. Flame Retardant Steel Cord Rubber Conveyor Belt

Type:QMH Steel Cord Conveyor Belt with Flame Retardant Properties

Material:Steel cords embedded in rubber

Features:Small Elongation, High Tensile Strength, Small Pulley Diameter Required, Excellent Flexing and Fatigue Resistance, Reliable Adhesion, Good Troughability, Uniform Tension of Steel Cord, X-ray Inspection Available during Operation

Applications:Suitable for long-distance and heavy-load transportation in mining, port operations, and other industrial sectors.

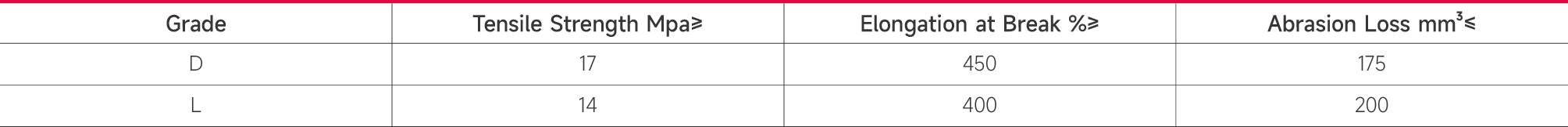

·Tensile Strength:≥15Mpa

·Elongation at Break:≥350%

·Abrasion Loss:≤200mmm³

·Aging Test (70℃*168h):Change of Tensile Strength ±25%~-25%/ Change of Elongation at Break ±25%~-25%

Compliance with Standards:QMH flame-retardant conveyor belts comply with international standards such as EN 14973, which specifies requirements for flame-resistant conveyor belts used underground.

Customizability:QMH belts can often be customized in terms of width, strength, cover material, and other specifications to meet specific application needs.

Testing and Certification:QMH typically conduct rigorous testing to ensure that our flame-retardant conveyor belts meet the required safety standards and obtain necessary certifications.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.