A H-type polyurethane pulley scraper is essential for conveyor systems operating in harsh mining conditions. Also known as a Pulley Scraper, its primary function is to remove bulk material from conveyor belts.

Send InquiryQMH H-type Polyurethane Pulley Scraper helps to prevent buildup and ensure efficient operation. They reduce the risk of belt damage, premature wear, and worker accidents by eliminating potential hazards associated with material accumulation.

QMH supplying high-quality H-type Polyurethane Pulley Scraper. They're designed to work with various belt sizes, speeds, and industries.

H-Type Polyurethane Pulley Scraper

Primary Polyurethane Pulley Scraper are essential for improving efficiency and durability in conveyor systems. The primary scraper has a more aggressive and robust blade to handle additional materials. The primary scraper is strategically positioned at the discharge end of the conveyor. This allows it to act as the first line of defense against carryback. It actively cleans the conveyor immediately after material transport.

QMH primary H-type Polyurethane Pulley Scraper is equipped with a unique scraping board made from a special polyurethane rubber and plastic composite . This composite material is carefully selected for its exceptional durability, wear resistance, and flexibility.

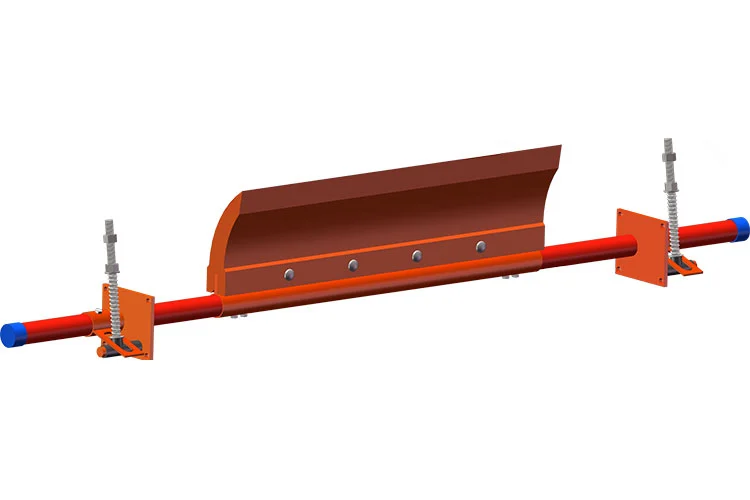

Thickened blade:

The scraping part of the HMZ blade is thickened, and the force tip adopts an arc surface to contact the belt surface, which increases the contact area, does not leak and has a long service life.

Reinforced material:

The polyurethane blade head is highly abrasion-resistant, highly elastic, acid and alkali resistant, low friction coefficient, and does not damage the belt.

Thick components:

The thickness of the mounting plates on both sides is 10mm and the thickness of the sleeve is 10mm, The sleeve is covered with a polyurethane buffer ring to play a buffering and shock-absorbing role.

Thick and beautiful rods:

The bracket rods are made of high-quality steel pipes, with good toughness and continuous shaft, and the surface is sprayed with plastic and painted, which is bright and beautiful

Applicable to the cleaning of residual materials on the belt surface of the belt conveyor unloading roller. Best suited for initial cleaning efforts where the bulk of material needs to be removed quickly and effectively Removal of Materials in Various Industries. The QMH H-Type Pulley Scraper is a versatile solution suitable for a wide range of industries, including but not limited to mining, energy, cement, and more. It effectively removes materials that adhere to the conveyor belt, such as bulk materials, aggregates, coal, and other industrial materials.

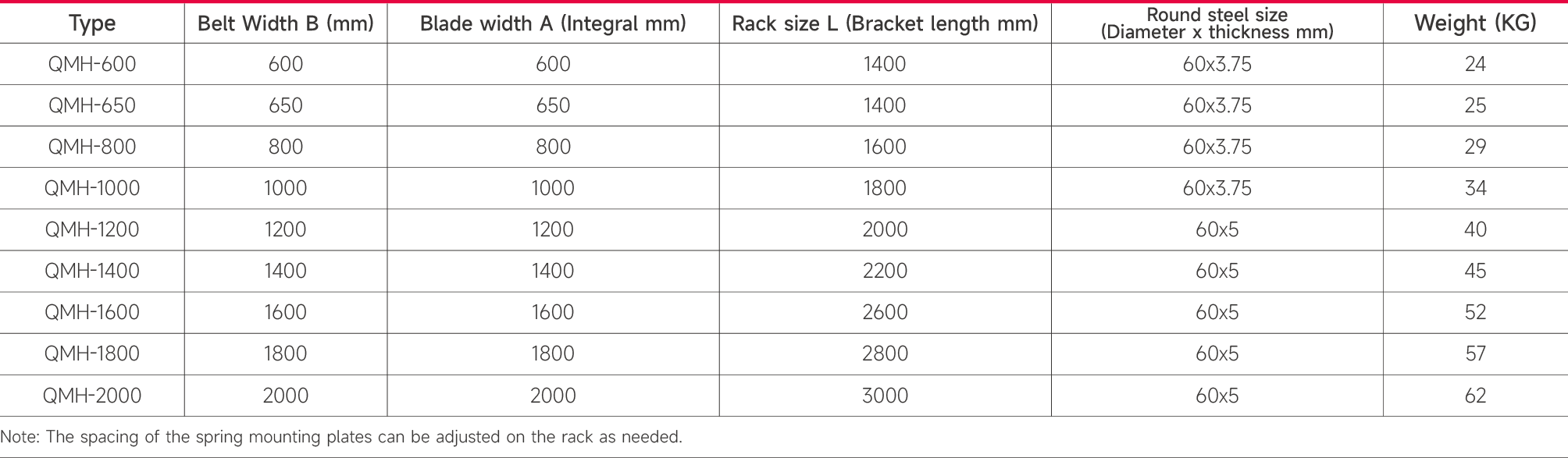

The H type polyurethane Pulley Scraper is designed to accommodate conveyor belts of specific widths and speeds. This customization ensures that it can effectively clean belts of various dimensions and operating conditions, making it adaptable to the specific requirements of different conveyor systems.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.