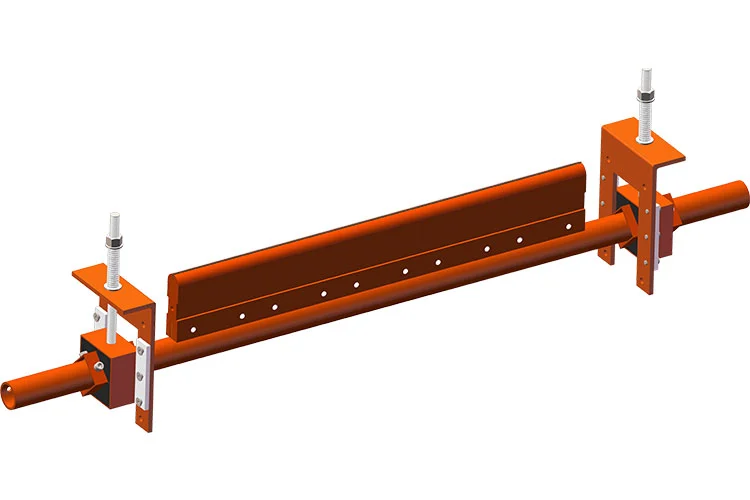

P-type Polyurethane Secondary Scraper have lighter and less aggressive blades. They’re positioned further down the conveyor line to remove any remaining carryback effectively. Their simple yet efficient design allows for seamless integration into existing conveyor systems.QMH P-type Polyurethane Secondary Scraper often feature softer, more flexible polyurethane blades or multiple blade setups that gently but firmly scrape away remaining residues, ensuring thorough cleaning with minimal belt wear.

Send InquiryQMH P-type Polyurethane Secondary Scraper are installed where the belt leaves the discharge pulley. Their purpose is to remove any material the primary cleaner missed. They are positioned close to the primary cleaner, so discharged material falls back into the main flow. Additional P-type Polyurethane Secondary Scraper provide final belt cleaning before the return idlers. QMH P-type Polyurethane Secondary Scraper play a pivotal role in achieving the highest level of belt cleanliness. They are specifically designed to address any residual carryback or fine materials that primary cleaners may not completely remove. This secondary cleaning action ensures that the conveyor belt remains as clean as possible, reducing the risk of material spillage and contamination.

QMH P-type Polyurethane Secondary Scraper are positioned just after the primary cleaners, they target the finer particles and residual materials that the first stage may not fully remove. They play a critical role in ensuring the belt is cleaned to a higher standard. QMH P-type Polyurethane Secondary Scraper is designed to work in conjunction with primary belt cleaners of H-type polyurethane pulley scraper, creating a two-tier cleaning system.

Cutter head: Integral polyurethane seamless without splicing, no leakage;

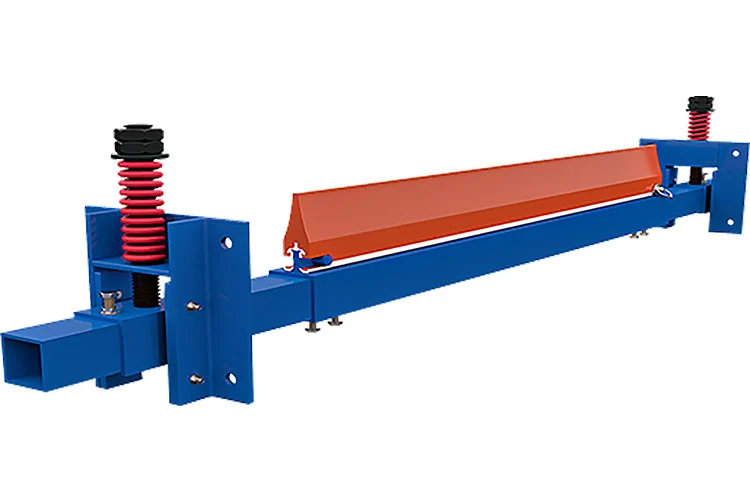

Tensioner: Thickened components, sleeve thickness 10mm, spring installation method can be upward/downward, easy to adjust;

Rods are thick and beautiful: The bracket rods are made of high-quality steel pipes, with good toughness and continuous shaft, and the surface is sprayed with plastic and painted, bright and beautiful.

Enhanced Cleaning: By complementing primary scrapers, the P-type Polyurethane Secondary Scraper ensures that any remaining fines, residues, or materials that may have escaped the primary cleaning process are efficiently removed. This dual approach to cleaning significantly improves overall belt cleanliness.

Reduced Wear and Tear: Because primary pulley scrapers do the initial heavy lifting, QMH P-type Polyurethane Secondary Scraper can focus on fine-tuning the cleaning process. This results in reduced wear on both the primary and secondary cleaning components, prolonging their service life.

Positioning Flexibility: QMH P-type Polyurethane Secondary Scraper can be installed beneath the head pulley or in other strategic locations along the conveyor system. This positioning flexibility ensures that they can target specific areas where carryback or fine materials are most likely to accumulate.

Vertical or Diagonal Installation: Depending on the conveyor's layout and material characteristics, QMH P-type Polyurethane Secondary Scraper can be installed vertically or diagonally. This adaptability allows for optimized cleaning in different scenarios.

QMH P-type Polyurethane Secondary Scraper are versatile and can be adapted to different conveyor belt widths. This adaptability allows them to cater to a wide range of conveyor systems, ensuring effective cleaning regardless of belt dimensions. Whether the conveyor belt is narrow or wide, QMH P-type Polyurethane Secondary Scraper can be configured to match its width.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.