QMH heat-resistant conveyor belt is a specialized type of conveyor belt designed to withstand high temperatures during operation. QMH heat-resistant belts are available for EP or steel cord carcass configurations to meet T1, T2 , T3, T4 applications with excellent resistance to high temperature, heat, aging and chemical, good troughability for stable conveying, high adhesive strength and Long service life. QMH heat-resistant conveyor belts are indispensable in industries requiring high-temperature resistance, providing efficient and reliable material handling solutions.

Send InquirySkeleton Layer:Typically made of metallic materials, providing the belt with structural support and tensile strength.

Covering Layer:Made primarily of rubber, such as styrene-butadiene rubber and chloroprene rubber. This layer is formulated with special additives, including sulfide crosslinking agents, activators, antioxidants, reinforcing agents, flame retardants, and other compounds like phosphoric acid esters, to enhance its heat resistance and durability.

QMH heat-resistant conveyor belts are applicable to metallurgy, cement, casting, power and chemical industries to handling high temperature materials such as sinter, coke and cement clinker, etc.

Metal Processing:Conveying hot metal slabs, ingots, and other materials in steel mills and foundries.

Cement and Mining:Transporting materials in kilns, furnaces, and mining operations where high temperatures are encountered.

Food Processing:In some specific food processing applications where heat treatment is required.

Chemical Industry:Handling chemicals and materials that may generate heat during processing or storage.

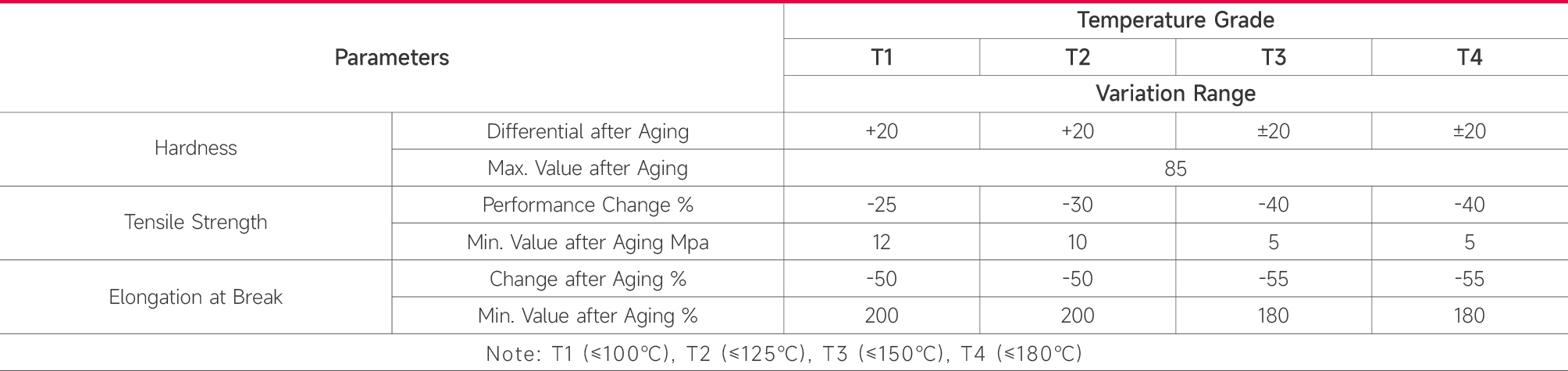

QMH can offer customization options to meet specific customer requirements, including different belt widths, thicknesses, tensile strengths, and cover rubber grades. QMH heat-resistant conveyor belts are typically manufactured to adhere to strict industry standards, ensuring their safety, reliability, and performance.

The production of QMH heat-resistant conveyor belts involves rigorous quality control processes, including raw material inspection, rubber compound testing, tensile strength and elongation tests, and advanced manufacturing techniques like calendering and forming processes, to guarantee the highest quality standards.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.