QMH oil-resistant conveyor belt is a conveyor belt that possesses the ability to resist oil. It is typically manufactured using materials that are resistant to oil absorption, swelling, and degradation, ensuring that it maintains its structural integrity and operational efficiency in oily environments.

Send InquiryOil-resistant conveyor belts are a critical component in many industrial applications where oil and other similar substances are present. QMH's special materials and construction make the belts highly durable and resistant to the corrosive effects of oil, ensuring smooth and efficient material handling. Proper installation, operation, and maintenance are essential to maximize the performance and service life of these belts.

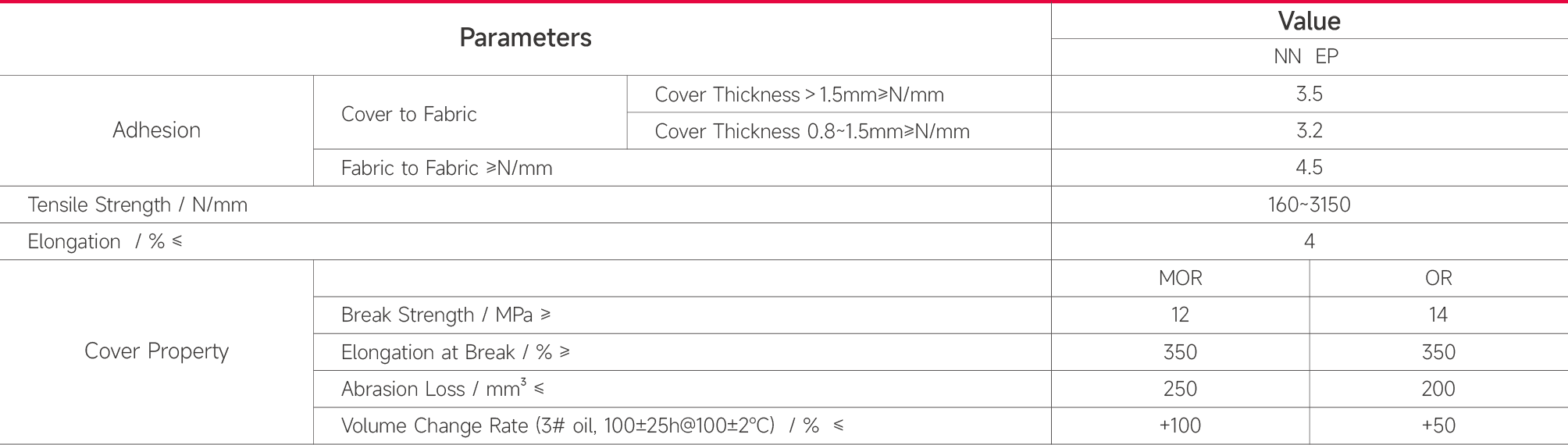

Core Materials:The core of an oil-resistant conveyor belt is usually made of high-strength, oil-resistant fabrics such as cotton canvas, nylon canvas, or EP (epoxy-coated) canvas. These materials provide good elasticity, troughability, and low elongation, ensuring stable operation of the belt.

Cover Rubber:The cover rubber of the belt is formulated with special compounds that are resistant to oil and other chemicals. This rubber layer protects the core materials from direct contact with oil and other corrosive substances, thereby prolonging the service life of the belt.

Oil Resistance:The primary characteristic of an oil-resistant conveyor belt is its ability to resist the corrosive effects of oil. This makes it suitable for use in environments where oil and other similar substances are present.

Durability:Due to its special materials and construction, QMH oil-resistant conveyor belt is highly durable and can withstand the wear and tear associated with continuous operation in industrial settings.

Flexibility:QMH belt maintains its flexibility even in oily conditions, allowing it to conform to the contours of the conveyor system and ensuring smooth material handling.

Enhanced Wear Resistance:QMH oil-resistant conveyor belts are formulated with special compounds that not only resist oil but also enhance wear resistance.

Heat Resistance:In addition to oil resistance, QMH can also design it to withstand high temperatures.

Low Elongation:QMH oil-resistant conveyor belts are designed to have low elongation properties, which ensures stable operation of the conveyor system and reduces the risk of belt slippage or misalignment.

Customization:Oil-resistant conveyor belts can be customized to meet specific application requirements. This includes varying the width, thickness, tensile strength, and cover rubber grade to suit different industrial needs.

Maintenance:Regular maintenance, such as cleaning and inspecting the belt for wear and tear, is essential to ensure the continued performance and service life of the belt. Additionally, replacing worn-out sections promptly can prevent costly downtime and repairs.

Fabric-Reinforced Belts:QMH fabric-reinforced oil-resistant conveyor belts are the most common type. They are made with a core of high-strength fabric, such as polyester or nylon, and a cover rubber layer that is resistant to oil and other chemicals.

Steel Cord Belts:QMH steel cord belts are stronger and more durable than fabric-reinforced belts. They are made with a core of steel cords embedded in rubber, and a cover rubber layer that is resistant to oil. QMH belts are typically used in heavy-duty applications where high tensile strength and long service life are required.

Solid Woven Belts:QMH solid woven belts are made from a single layer of woven fabric, which is then impregnated with rubber to form a continuous, seamless belt. QMH belts are highly resistant to oil and chemicals, and are often used in applications where cleanliness and hygiene are critical.

QMH oil-resistant conveyor belts are manufactured to meet industry standards and certifications, ensuring their quality, safety, and performance. We QMH follow the international standards and certifications:

DIN 22102:A German standard that specifies the requirements for rubber conveyor belts for general use.

ISO/TR 10555:An international technical report that provides guidance on the selection of conveyor belts for specific applications.

RMA (Rubber Manufacturers Association):A U.S.-based organization that develops standards and specifications for rubber conveyor belts.

Installation:Oil-resistant conveyor belts should be installed by trained personnel using proper tools and techniques. The belt should be tensioned to the correct tension to ensure stable operation and prevent premature wear.

Operation:During operation, the belt should be monitored regularly for signs of wear, tear, or damage. The conveyor system should be maintained in good working condition, with all moving parts properly lubricated and aligned.

Cleaning:QMH would suggest a regular clean to remove any build-up of oil, grease, or other contaminants. This helps to maintain the belt's performance and extend its service life.

Inspection:Regular inspections should be conducted to check for signs of wear, tear, or damage. Any damaged sections of the belt should be repaired or replaced promptly to prevent further damage and downtime.

Replacement:When the belt reaches the end of its service life, it should be replaced with a new one. It is important to select a belt that meets the specific requirements of the application, including width, thickness, tensile strength, and cover rubber grade.

If you have any enquiry about quotation or cooperation, please feel free to email or use the following inquiry form. Our sales representative will contact you within 24 hours.